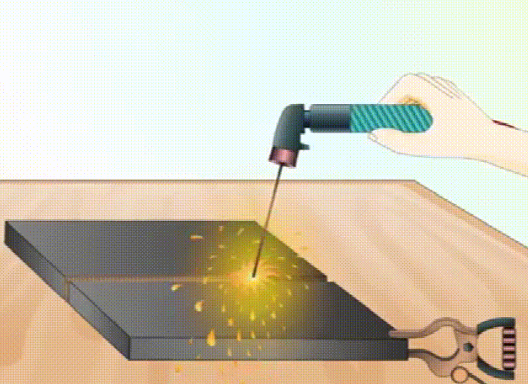

1, Electrode arc Welding

I-arc welding ingenye yamakhono ayisisekelo kakhulu ama-welders awazi kahle, uma amakhono engekho, kuzoba namaphutha ahlukahlukene kumthungo wokushisela.

2, ukushisela i-arc emanzini

I-arc welding engaphansi kwamanzi iyindlela yokushisela esebenzisa i-arc njengomthombo wokushisa. Ngenxa yokungena okujulile kwe-arc welding engaphansi kwamanzi, izinga lokushisela lihle: ngenxa yokuvikelwa kwe-slag encibilikisiwe, insimbi encibilikisiwe ayixhumani nomoya, futhi izinga lokusebenza kwemishini liphezulu, ngakho-ke ifaneleka ukushisela. amashisela amade ezakhiwo zamapuleti aphakathi nendawo.

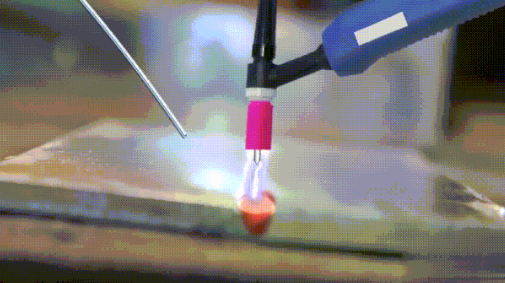

3. I-Argon arc welding

Nazi ezinye izinyathelo zokuphepha ze-argon arc welding:

(1) Inalithi ye-tungsten kufanele ilolwe njalo. Uma buthuntu, i-current ngeke igxiliswe futhi ukushisela kuzoqedwa.

(2) Uma ibanga phakathi kwenaliti ye-tungsten ne-weld liseduze kakhulu, zizonamathela ndawonye. Uma ikude kakhulu, i-arc izoqhakaza. Uma i-arc iqhakaza, izoshisa ibe mnyama futhi inaliti ye-tungsten izoba nempandla. I-radiation to the self nayo inamandla. Kungcono ukuyigcina iseduze.

(3) Ukulawula iswishi kuwubuciko, ikakhulukazi bokushisela amapuleti amancane. Ingavulwa kuphela ngayinye ngayinye. Lona akuwona umshini wokushisela ozenzakalelayo onokunyakaza okuzenzakalelayo kanye nokudla okuzenzakalelayo kocingo. Uma ivutha njalo, izoguga.

(4) Udinga ukuphakela ucingo. Lokhu kudinga umuzwa wokuthinta. Intambo yokushisela esezingeni eliphezulu inqunywa kumapuleti angama-304 ngomshini wokugunda. Ungayithengi ibe yinqwaba. Yiqiniso, ungathola ezinhle ezindaweni ezithengisa kakhulu.

(5) Zama ukusebenza ezindaweni ezingenawo umoya, gqoka amagilavu esikhumba, izingubo zokugqoka, kanye ne-automatic dimming mask.

(6) Ikhanda le-ceramic lesibhamu sokushisela kufanele livikelwe ku-arc. Ngokuqondile, umsila wesibhamu sokushisela kufanele uqondiswe ebusweni bakho ngangokunokwenzeka.

(7) Uma ungaba nombono kanye nesandulela mayelana nezinga lokushisa, usayizi, kanye nesenzo sechibi elincibilikisiwe, unguchwepheshe omkhulu.

(8) Zama ukusebenzisa izinaliti ze-tungsten ezinezimpawu eziphuzi noma ezimhlophe, njengoba lokhu kudinga ubuciko obuphezulu.

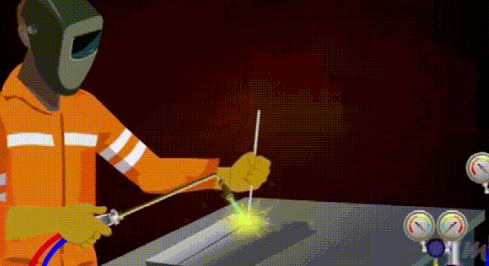

4. I-oxygen fuel gas welding

I-oxygen fuel gas welding ukusetshenziswa kwamalangabi ukushisa insimbi nentambo yokushisela ekuhlanganyeleni kwezinto zokusebenza zensimbi ukuze zincibilike futhi kuzuzwe inhloso yokushisela. Amagesi avuthayo asetshenziswa kakhulu ikakhulukazi i-acetylene, i-liquefied petroleum gas ne-hydrogen, kanti igesi evame ukusetshenziswa kakhulu esekela ukuvutha umoya-mpilo.

5. Laser Welding

I-laser welding iyindlela yokushisela ephumelelayo nenembayo esebenzisa isigxobo selaser esinamandla amakhulu njengomthombo wokushisa. I-Laser Welding ingenye yezinto ezibalulekile ekusetshenzisweni kobuchwepheshe bokucubungula izinto ze-laser. Ngawo-1970, yayisetshenziselwa kakhulu ukushisela izinto ezinezindonga ezincane kanye nokushisela okunesivinini esiphansi. Inqubo yokushisela iwuhlobo lwe-heat conduction, okungukuthi, imisebe ye-laser ishisa ingaphezulu le-workpiece, futhi ukushisa okungaphezulu kusabalele ngaphakathi ngokusebenzisa ukushisa kokushisa. Ngokulawula ububanzi, amandla, amandla aphezulu kanye nemvamisa yokuphindaphinda kwe-laser pulse, ucezu lokusebenza luyancibilika ukwenza ichibi elithile elincibilikisiwe.

Isikhathi sokuthumela: Oct-22-2024