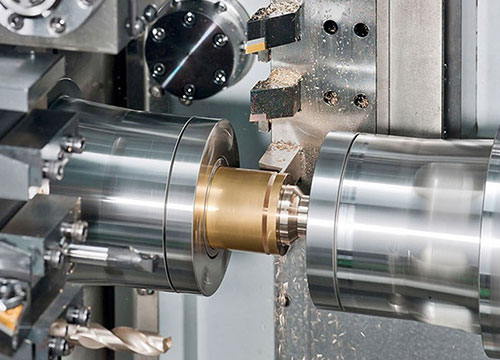

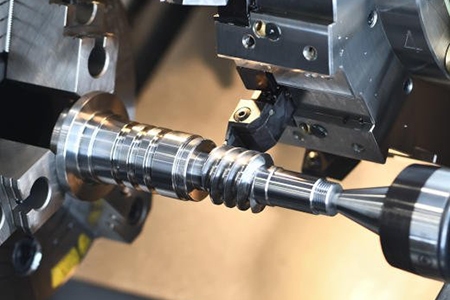

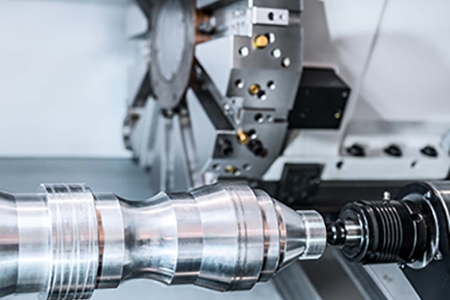

CNC Turning Services

I-CNC Turning isetshenziselwa kakhulu ukusika izindawo eziyisilinda zangaphakathi nezangaphandle zezingxenye zeshaft noma izingxenye zediski, indawo eyindilinga yangaphakathi nangaphandle yama-engeli ekhoni engafanele, izindawo eziyinkimbinkimbi ezijikelezayo zangaphakathi nezingaphandle ezigobile, amasilinda, imicu eyikhonikhi, njll. Ngokusho kwe-pre-programmed Uhlelo lokucubungula, lungakwazi ukucubungula izingxenye ezinembayo ezifana ne-grooving, ukubhoboza, ukulungisa kabusha, ukuphinda futhi kubhora.

±0.005MM (√)Ra0.2

Umshini we-CNC Unezici Ezilandelayo

● Ukunemba okuphezulu kokucubungula kanye nekhwalithi yokucubungula ezinzile;

● Ingakwazi ukuxhumanisa ama-multi-coordinate, izinga eliphezulu lokuzishintshanisa, futhi ingacubungula izingxenye ezinobumo obuyinkimbinkimbi;

● Lapho ushintsha izingxenye zokucubungula, ngokuvamile kudingeka kuphela ukushintsha uhlelo lwe-NC, olungasindisa isikhathi sokulungiselela ukukhiqiza futhi luthuthukise ukusebenza kahle;

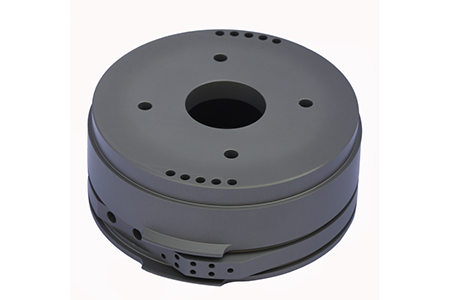

Izingxenye Zomshini Wokunemba Eziqinisekiswe Ikhwalithi Ephezulu

I-K-TEK inemishini yokucubungula ethuthukisiwe, ithimba lonjiniyela elihle kakhulu, kanye nemodi yokusebenza ephumelelayo.Ihlinzeka amakhasimende ngezinsizakalo zokuguqula ze-CNC ezisezingeni eliphezulu nezisebenza kahle ngamanani ancintisanayo, futhi iguqule imidwebo yokuklama yobunjiniyela ecophelelayo ibe izingxenye ezihlukahlukene ezinembayo.

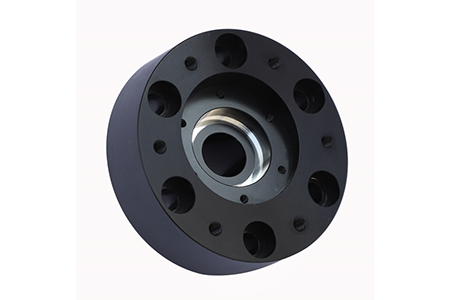

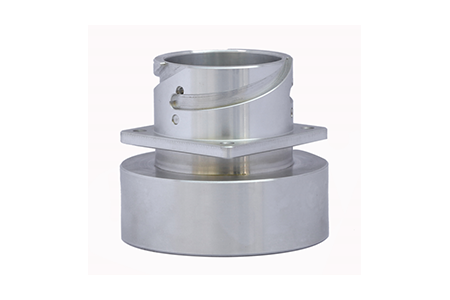

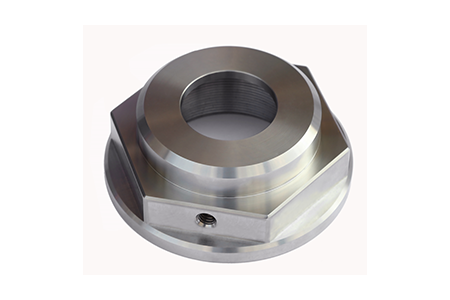

Ukwenza ngokwezifiso izingxenye ze-lathe

Izimfuneko Zokunemba Zezingxenye Ezishintshayo Ngokwezifiso

| Ukunemba komshini | |

| ngokuvamile ingahlangabezana nezidingo | |

| ukunemba komshini | ±0.005 MM |

| (√) | I-Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

| Inani Le-oda Elincane(I-MOQ)≥1 | |

Ukukhanda Izinto Ezisetshenziswa Ngokujwayelekile Nokwelashwa Kwangaphandle

Izingxenye zokunemba ezihlukene zingasebenzisa izinto ezahlukahlukene ngokuya ngezidingo zokuklama komkhiqizo.Singakwazi ukucubungula izinto ezihlukahlukene kanye nokwelashwa kwendawo ukuze sihlangabezane nezidingo zamakhasimende.Izinto ezisetshenziswayo ezijwayelekile kanye nokwelashwa kwangaphezulu imi kanje:

| Izinto ezijwayelekile nokwelashwa kwendawo | ||

| Okuvamile Izinto zokwakha | Insimbi | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, I-S50C, 65Mn, I-SCM415, 40Kr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, I-SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, I-SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, I-SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, I-ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, I-HPM1, HPM77, HPM75, 718H, 738H, DF-3, njll. | ||

| I-Aluminium | I-LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, I-MIC-6, njll. | ||

| Insimbi engagqwali | I-SUS201, I-SUS321, I-SUS301, I-SUS303, I-SUS304, I-SUS304L, S136, I-S136H, ,I-SUS316, I-SUS316L, I-SUS316Ti | |

| I-SUS321, I-SUS420, 17-4ph, 430F, I-X90CrMoV18, 9Cr18MoV, I-SUS440, njll. | ||

| Ithusi | T2, TU1/2, I-TP1/2, ,Ithusi, Ithusi, Ibhulonzi, I-CuZn38Sn1, CuZn39Pb3, I-CuSn12, I-CuSn8P, C-360 | |

| I-CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, I-C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| I-HPb61-1, QSn7-02, C-954/514QAI 10-4-4, I-AMPCOM4, H59, H62, CuZN30, CuSn37, njll. | ||

| Ipulasitiki | I-PEEK, I-PEEK1000, I-POM, I-TEFLON, I-PTFE, I-PET, UHMW-PE, I-HMW-PE, I-PEI, PI, PP, I-PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, I-MC501CDR6, I-PPO, I-NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, I-PBT, I-PET, I-PET+30%GF, PC, I-PC+30%GF, Inayiloni, I-ABS, ESD225/420/520, njll. | ||

| Ukwelashwa kwendawo | Sula u-Anodize, U-Anodize omnyama, Ubulukhuni Anodize, I-Anodize eluhlaza okwesibhakabhaka/Ebomvu, I-Chromate Plating, QPQ | |

| I-Electroless Nickel/Nine/Chromium Plate, I-Black oxide, Isiliva\Golden Plating, Isihlabathi, I-DLC | ||

| I-Orbital Sanded, Iphasisiwe, I-TIN PlatingTungsten Carbide Coating, Ukufakwa kwe-polyurethae, njll. | ||