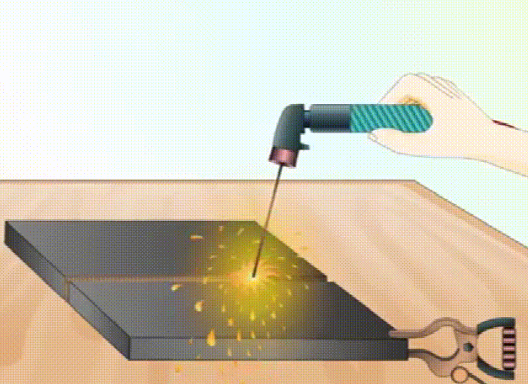

1, Electrode arc welding

I-arc welding yenye yezona zakhono zisisiseko ze-welders master, ukuba izakhono azikho, kuya kubakho iziphene ezahlukeneyo kwi-welding seam.

2, ukuwelda kwe-arc emanzini

I-arc welding ephantsi kwamanzi yindlela yokudibanisa usebenzisa i-arc njengomthombo wokushisa. Ngenxa yokungena okunzulu kwe-arc welding ephantsi kwamanzi, umgangatho we-welding ulungile: ngenxa yokukhusela i-slag etyhidiweyo, isinyithi esinyibilikisiweyo asidibanisi nomoya, kwaye iqondo lokusebenza komatshini liphezulu, ngoko lifanelekile ukuwelda. iiweld ezinde zezakhiwo zeepleyiti eziphakathi kunye nezityebileyo.

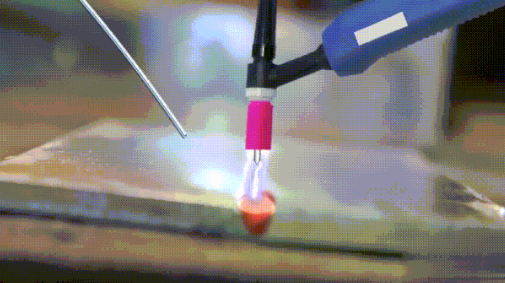

3. Argon arc welding

Nazi ezinye izilumkiso ze-argon arc welding:

(1) Inaliti yetungsten ifanele ilolwe rhoqo. Ukuba i-blunt, yangoku ayiyi kugxininiswa kwaye i-welding iya kugqitywa.

(2) Ukuba umgama phakathi kwenaliti ye-tungsten kunye ne-weld usondele kakhulu, baya kunamathela kunye. Ukuba ikude kakhulu, i-arc iya kudumba. Nje ukuba i-arc iqhakaze, iya kutshisa ibe mnyama kwaye inaliti ye-tungsten iya kuba nempandla. I-radiation kwi-self nayo yomelele. Kungcono ukuyigcina ikufutshane.

(3) Ulawulo lokutshintsha lubugcisa, ngakumbi kwi-welding plate ebhityileyo. Ingavulwa kuphela nganye nganye. Lo ayisiwo umatshini we-welding ozenzekelayo kunye nokunyakaza okuzenzekelayo kunye nokutya okuzenzekelayo ngocingo. Ukuba ivutha rhoqo, iya kuphelelwa ngamandla.

(4) Kufuneka utyise ucingo. Oku kufuna imvakalelo yokubamba. I-high-quality welding wire inqunywe kwiipleyiti ze-304 ngomatshini wokucheba. Musa ukuyithenga ibe zizithungu. Ewe kunjalo, ungazifumana ezilungileyo kwiindawo ezithengiswayo.

(5) Zama ukusebenza phantsi kweemeko zokungena umoya, nxiba iiglavu zesikhumba, impahla, kunye nesigqubuthelo sobuso esizikhanyelayo.

(6) Intloko ye-ceramic ye-welding gun kufuneka ikhuselwe kwi-arc. Ngokukodwa, umsila we-welding gun kufuneka ubhekiswe ebusweni bakho kangangoko kunokwenzeka.

(7) Ukuba unokuba ne-intuition kunye ne-premonition malunga nobushushu, ubungakanani, kunye nesenzo sedama elityhidiweyo, uligcisa eliphezulu.

(8) Zama ukusebenzisa iinaliti zetungsten ezineempawu ezimthubi okanye ezimhlophe, njengoko oku kufuna ubugcisa obuphezulu.

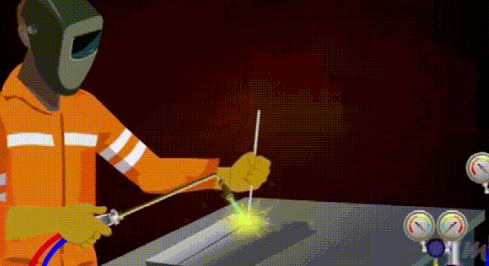

4. I-oxygen fuel welding gas welding

I-oxygen fuel welding gas welding kukusetyenziswa kwamadangatye ukutshisa isinyithi kunye nocingo lwe-welding ekudibaneni kwezinto zokusebenza zetsimbi ukuze zinyibilike kwaye zifezekise injongo ye-welding. Iirhasi ezitsha ezisetyenziswa ngokuqhelekileyo ikakhulu yi-acetylene, i-liquefied petroleum gas kunye ne-hydrogen, kwaye igesi esetyenziswa ngokuqhelekileyo exhasa ukutsha yioksijini.

5. Laser welding

I-laser welding yindlela esebenzayo kunye nechanekileyo ye-welding esebenzisa i-high-energy-density laser beam njengomthombo wobushushu. Ukuwelda kweLaser yenye yezinto ezibalulekileyo ekusetyenzisweni kobuchwepheshe bokusetyenzwa kwe-laser. Ngeminyaka yee-1970, yayisetyenziselwa ukuwelda izixhobo ezinodonga olucekethekileyo kunye nesantya esisezantsi sokuwelda. Inkqubo ye-welding luhlobo lokuqhuba ubushushu, oko kukuthi, i-laser radiation itshisa umphezulu we-workpiece, kwaye ubushushu bomhlaba busasazeka ngaphakathi ngokuqhuba ubushushu. Ngokulawula ububanzi, amandla, amandla aphezulu kunye nokuphindaphinda ukuphindaphinda kwe-laser pulse, i-workpiece iyanyibilika ukwenza ichibi elithile elityhidiweyo.

Ixesha lokuposa: Oct-22-2024