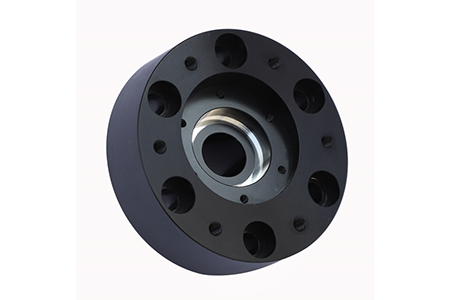

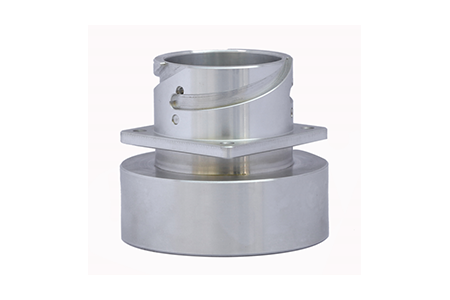

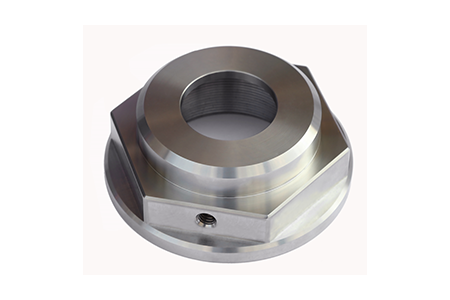

Iinkonzo zokuguqula i-CNC

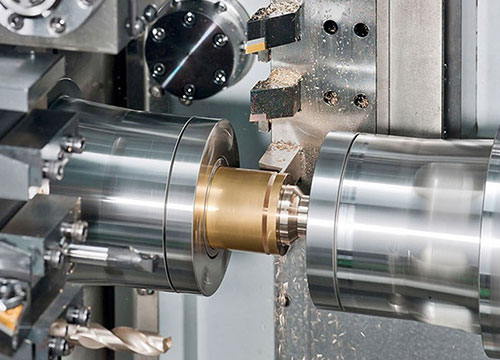

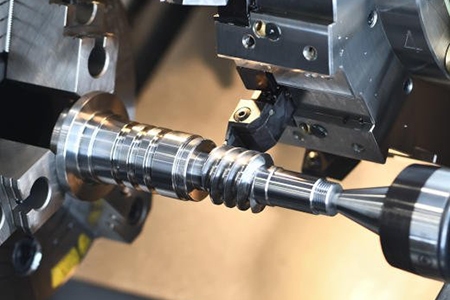

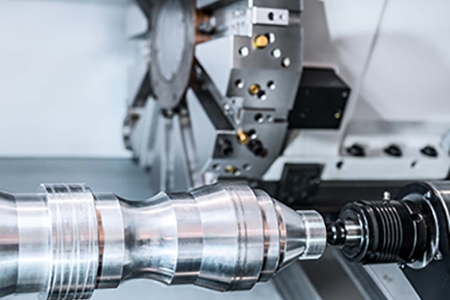

I-CNC Turning isetyenziselwa ikakhulu ukusika imiphezulu ye-cylindrical yangaphakathi nangaphandle ye-shaft parts okanye ii disk parts, i-conical surfaces zangaphakathi nangaphandle zee-engile ze-cone ezingaqondakaliyo, i-rotary eyinkimbinkimbi yangaphakathi nangaphandle egobileyo, iisilinda, i-conical threads, njl. inkqubo yokusetyenzwa, iyakwazi ukuqhubekekisa iindawo ezichanekileyo ezinje ngokugrumba, ukugrumba, ukubuyisela kwakhona, ukubuyisela kwakhona kunye nokudika.

±0.005MM (√)Ra0.2

Umatshini we-CNC uneeNkalo ezilandelayo

● Ukuchaneka okuphezulu kunye nomgangatho ozinzileyo wokusetyenzwa;

● Iyakwazi ukwenza unxibelelwano lwe-multi-coordinate, iqondo eliphezulu lokuzisebenzela, kwaye inokuqhuba iinxalenye ezinemilo enzima;

● Xa utshintsha iindawo zokucubungula, ngokuqhelekileyo kufuneka utshintshe inkqubo ye-NC kuphela, enokugcina ixesha lokulungiselela imveliso kunye nokuphucula ukusebenza kakuhle;

Izahlulo zoomatshini ezichanekileyo ezinoMgangatho oPhezulu oqinisekisiweyo

I-K-TEK inezixhobo zokusebenza eziphambili, iqela lobunjineli eligqwesileyo, kunye nemowudi yokusebenza esebenzayo.Ibonelela abathengi ngeenkonzo zokuguqula ezikumgangatho ophezulu kunye nezisebenzayo ze-CNC ngamaxabiso akhuphisanayo, kwaye iguqule imizobo yoyilo lobunjineli obucokisekileyo kwiindawo ezahlukeneyo ezichanekileyo.

Ukucutshungulwa ngokwesiko kwamalungu e-lathe

IiMfuno ezichanekileyo kwiiNdawo zokuTshintsha ngokweSiko

| Ukuchaneka komatshini | |

| inokuhlangabezana ngokubanzi neemfuno | |

| ukuchaneka komatshini | ±0.005 MM |

| (√) | Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

| Mini Order Ubungakanani(MOQ)≥1 | |

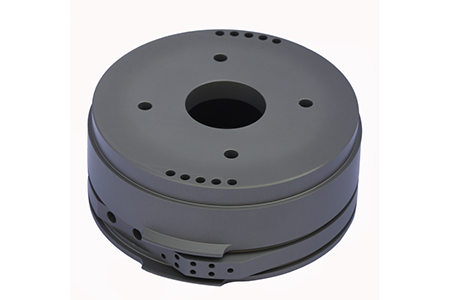

Machining ezisetyenziswa ngokuqhelekileyo Materials & Surface Treatment

Amacandelo achanekileyo angasebenzisa izinto ezahlukeneyo ngokweemfuno zoyilo lwemveliso.Singakwazi ukucubungula izixhobo ezahlukeneyo kunye nonyango lwangaphandle ukuhlangabezana neemfuno zabathengi.Imathiriyeli eqhelekileyo kunye nonyango lomphezulu lulandelayo:

| Izixhobo eziqhelekileyo kunye nonyango loMphezulu | ||

| Eqhelekileyo Izinto eziphathekayo | Intsimbi | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, I-SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, I-SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, I-SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, njl. | ||

| Aluminiyam | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, I-MIC-6, njl. | ||

| Yenziwe ngentsimbi eshayinayo | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H, ,SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, njl. | ||

| Ubhedu | T2, TU1/2, TP1/2, ,Ubhedu, Ubhedu, Ubhedu, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, I-AMPCOM4, H59, H62, CuZN30, CuSn37, njl. | ||

| Iplastiki | PEEK, I-PEEK1000, I-POM, I-TEFLON, PTFE, I-PET, UHMW-PE, HMW-PE, I-PEI, PI, PP, I-PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, I-MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, I-PET, I-PET+30%GF, PC, I-PC+30%GF, Inayiloni, ABS, ESD225/420/520, njl. | ||

| Unyango lomphezulu | Cacisa u-Anodize, Black Anodize, Ubunzima Anodize, Blue / Red Anodize, I-Chromate Plating, QPQ | |

| Electroless Nickel/Nine/Chromium Plate, I-oksidi emnyama, Silver\Golden plating, Isanti, I-DLC | ||

| I-Orbital Sanded, Igqithisiwe, TIN PlatingTungsten Carbide Coating, Polyurethae ukutyabeka, njl. | ||