Huduma za Kugeuza za CNC

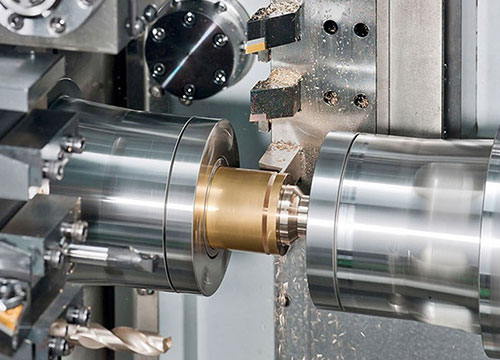

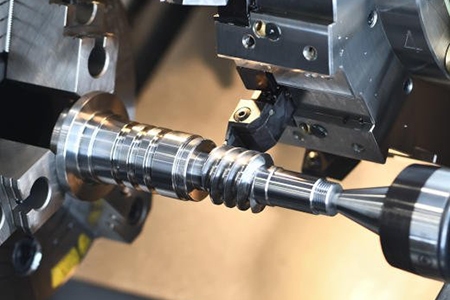

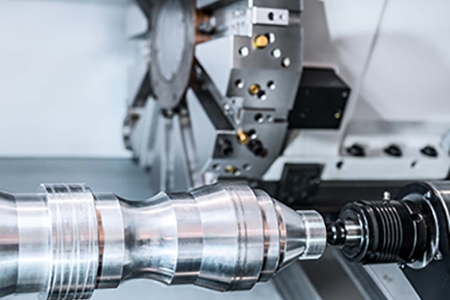

CNC Turning hutumiwa hasa kwa kukata nyuso za ndani na nje za silinda za sehemu za shimoni au sehemu za diski, nyuso za ndani na za nje za pembe za koni za kiholela, nyuso za ndani na za nje zilizopinda za Rotary, mitungi, nyuzi za conical, nk Kulingana na iliyopangwa awali. programu ya usindikaji, inaweza kuchakata sehemu za usahihi kama vile kuchimba visima, kuchimba visima, kuweka tena upya, kuweka upya na kuchosha.

±0.005MM (√)Ra0.2

Mashine ya CNC Ina Sifa Zifuatazo

● Usahihi wa juu wa usindikaji na ubora thabiti wa usindikaji;

● Inaweza kutekeleza uunganisho wa uratibu-nyingi, kiwango cha juu cha otomatiki, na inaweza kuchakata sehemu zenye maumbo changamano;

● Wakati wa kubadilisha sehemu za usindikaji, kwa ujumla zinahitaji tu kubadilisha programu ya NC, ambayo inaweza kuokoa muda wa maandalizi ya uzalishaji na kuboresha ufanisi;

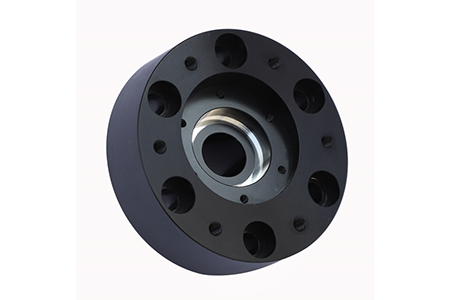

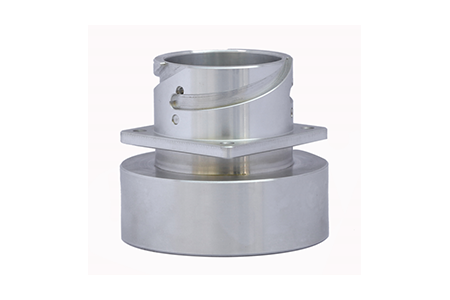

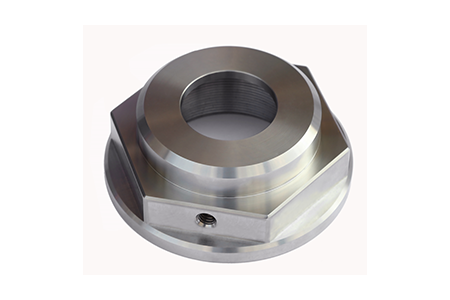

Sehemu za Mashine za Usahihi Zilizothibitishwa Ubora wa Juu

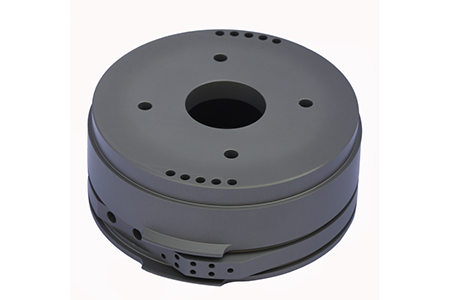

K-TEK ina vifaa vya hali ya juu vya usindikaji, timu bora ya uhandisi, na hali ya utendakazi bora.Inawapa wateja huduma za hali ya juu na bora za kugeuza CNC kwa bei shindani, na kubadilisha michoro ya usanifu wa uhandisi wa uangalifu katika sehemu mbalimbali za usahihi.

Uchimbaji maalum wa sehemu za lathe

Mahitaji ya Usahihi kwa Sehemu Maalum za Kugeuza

| Usahihi wa machining | |

| inaweza kukidhi mahitaji kwa ujumla | |

| usahihi wa usindikaji | ±0.005 MM |

| (√) | Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

| Kiasi cha Agizo la Mini(MOQ)≥1 | |

Uchimbaji Nyenzo Zinazotumika Kawaida & Matibabu ya uso

Sehemu tofauti za usahihi zinaweza kutumia vifaa tofauti kulingana na mahitaji ya muundo wa bidhaa.Tunaweza kusindika nyenzo na matibabu mbalimbali ili kukidhi mahitaji ya wateja.Nyenzo za kawaida na matibabu ya uso ni kama ifuatavyo.

| Nyenzo za kawaida na matibabu ya uso | ||

| Kawaida Nyenzo | Chuma | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Kr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAL, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, na kadhalika. | ||

| Alumini | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, na kadhalika. | ||

| Chuma cha pua | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H,,SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, na kadhalika. | ||

| Shaba | T2, TU1/2, TP1/2,,Shaba, Shaba, Shaba, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, na kadhalika. | ||

| Plastiki | PEEK, PEEK1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, PET, PET+30%GF, PC, Kompyuta+30%GF, Nylon, ABS, ESD225/420/520, na kadhalika. | ||

| Matibabu ya uso | Futa Anodize, Anodize nyeusi, Ugumu Anodize, Bluu/Nyekundu Anodize, Uwekaji wa Chromate, QPQ | |

| Nikeli Isiyo na Electroless/Tisa/Chromium Plate, Oksidi Nyeusi, Mchoro wa fedha\Dhahabu, Imepigwa mchanga, DLC | ||

| Mchanga wa Orbital, Imepitishwa, TIN PlatingTungsten Carbide Coating, Mipako ya polyurethae, na kadhalika. | ||