Jasa Ngaktipkeun CNC

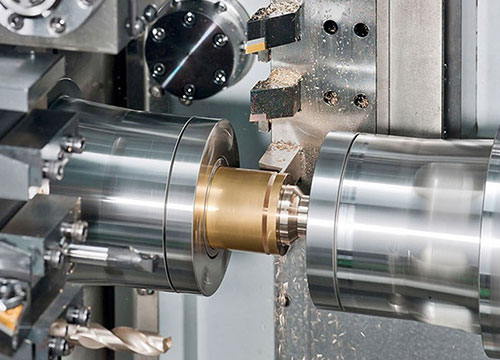

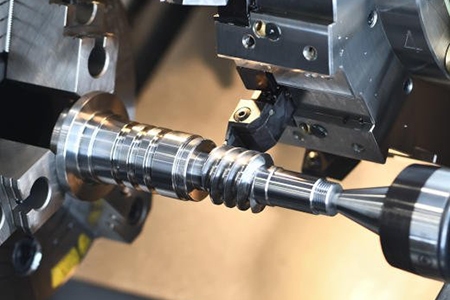

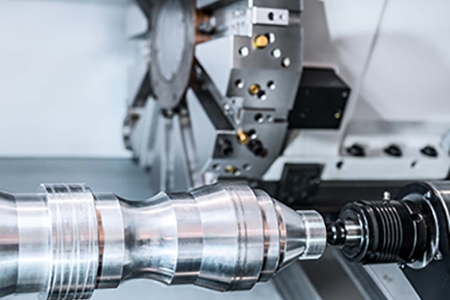

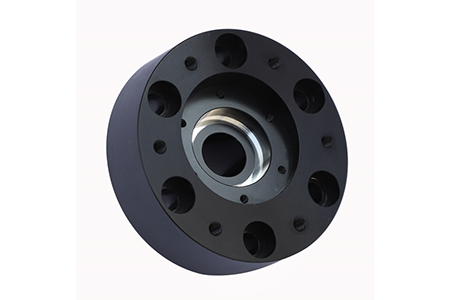

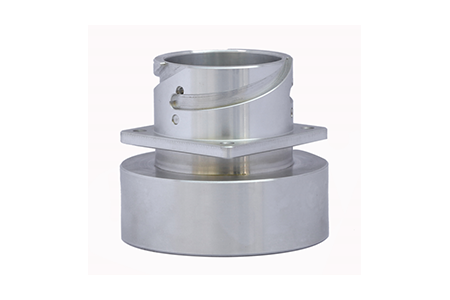

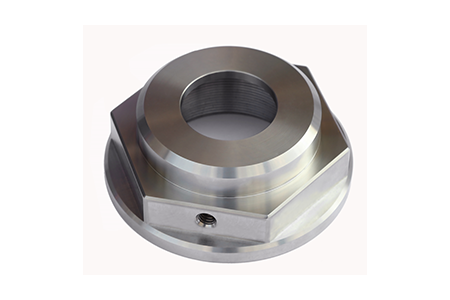

CNC Ngaktipkeun utamana dipaké pikeun motong surfaces cylindrical jero jeung luar bagian aci atawa bagian disk, surfaces kerucut jero jeung luar tina sudut congcot sawenang, kompléks Rotary surfaces jero tur luar melengkung, silinder, threads kerucut, jsb Nurutkeun kana pre-diprogram. program processing, éta bisa ngolah bagian precision kayaning grooving, pangeboran, reaming, reaming na boring.

± 0,005MM (√)Ra0,2

Mesin CNC Mibanda Ciri di handap ieu

● High processing precision jeung kualitas processing stabil;

● Bisa ngalaksanakeun multi-koordinat beungkeut, gelar luhur ti automation, sarta bisa ngolah bagian kalawan wangun kompléks;

● Lamun ngaganti bagian processing, umumna ngan perlu ngarobah program NC, nu bisa ngahemat waktu persiapan produksi jeung ningkatkeun efisiensi;

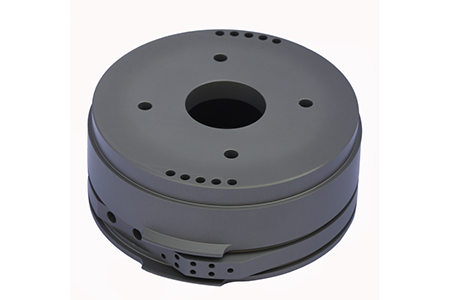

Bagian Machined Precision Jeung Quality High Dijamin

K-TEK gaduh alat pangolahan canggih, tim rékayasa anu saé, sareng mode operasi anu efisien.Eta nyadiakeun konsumén jeung kualitas luhur tur efisien jasa balik CNC kalawan harga kalapa, sarta transforms meticulous gambar desain rékayasa kana sagala rupa bagian precision.

Machining custom tina bagian lathe

Sarat Precision pikeun Custom Ngaktipkeun Bagian

| Akurasi mesin | |

| umumna tiasa nyumponan sarat | |

| akurasi mesin | ± 0,005 MM |

| (√) | Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

| Mini Order kuantitas(MOQ)≥1 | |

Machining Bahan Ilahar Dipaké & Perlakuan Permukaan

bagian precision béda bisa ngagunakeun bahan béda nurutkeun sarat desain produk.Urang bisa ngolah rupa-rupa bahan jeung perlakuan permukaan pikeun minuhan sarat customer.Bahan umum sareng perawatan permukaan nyaéta kieu:

| bahan umum & perlakuan Surface | ||

| Biasa Bahan | Baja | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, jsb. | ||

| alumunium | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, jsb. | ||

| Beusi sténless | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H,,SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4 jam, 430F, X90CrMoV18, 9Cr18MoV, SUS440, jsb. | ||

| Tambaga | T2, TU1/2, TP1/2,,Kuningan, Tambaga, Perunggu, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, jsb. | ||

| palastik | ngintip, NGINTIP1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66 + 30% GF, PBT, PET, PET + 30% GF, PC, PC+30%GF, Nilon, ABS, ESD225/420/520, jsb. | ||

| Perlakuan permukaan | Jelas Anodize, Hideung Anodize, Teuas Anodize, Bulao / Beureum Anodize, Kromat Plating, QPQ | |

| Electroless nikel / salapan / Lempeng Kromium, Hideung Oksida, Pérak \ Emas plating, diampeurkeun, DLC | ||

| Orbital diamplas, Pasif, TIN PlatingTungsten Carbide palapis, Lapisan polyurethae, jsb. | ||