Litšebeletso tsa ho fetola CNC

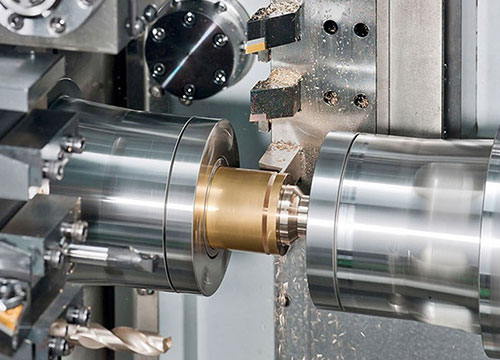

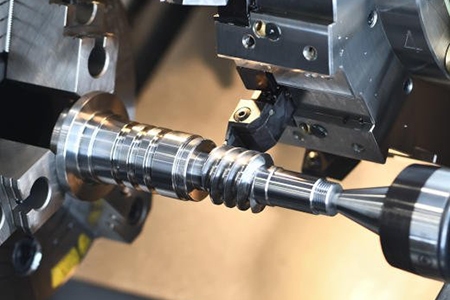

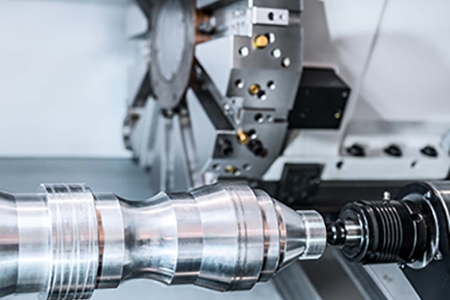

CNC Turning e sebelisoa haholo-holo bakeng sa ho seha libaka tse ka hare le tsa ka ntle tsa cylindrical tsa likarolo tsa shaft kapa likarolo tsa disk, bokaholimo ba ka hare le bo ka ntle ba li-angles tsa cone, tse rarahaneng tse pota-potileng ka hare le ka ntle, li-cylinders, likhoele tsa conical, joalo-joalo Ho latela se hlophisitsoeng esale pele. Lenaneo la ho sebetsa, le khona ho sebetsana le likarolo tse nepahetseng joalo ka grooving, drilling, reaming, reaming le ho tena.

±0.005MM (√)Ra0.2

Mochini oa CNC o na le Litšobotsi tse latelang

● Ho nepahala ho phahameng ho sebetsa le boleng bo tsitsitseng ba ho sebetsa;

● E ka etsa khokahano ea li-multi-coordinate, boemo bo phahameng ba boiketsetso, 'me e khona ho sebetsana le likarolo tse nang le libopeho tse rarahaneng;

● Ha ho nkeloa sebaka sa likarolo tsa ts'ebetso, ka kakaretso ho hlokahala feela ho fetola lenaneo la NC, le ka bolokang nako ea ho lokisetsa tlhahiso le ho ntlafatsa katleho;

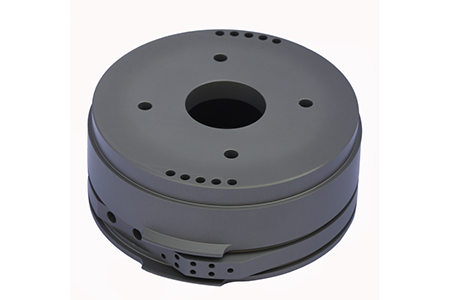

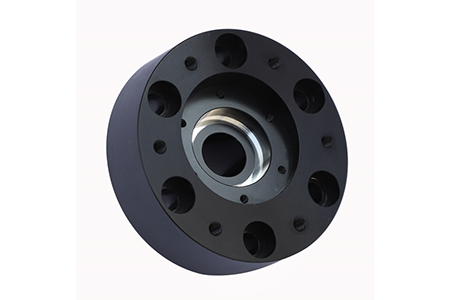

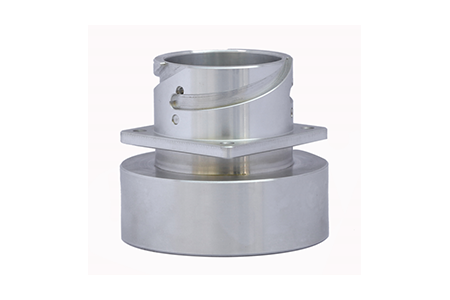

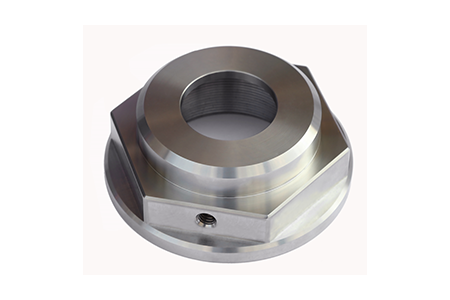

Likarolo tse entsoeng ka nepo tse nang le boleng bo holimo tse netefalitsoeng

K-TEK e na le lisebelisoa tse tsoetseng pele tsa ho sebetsa, sehlopha se setle sa boenjiniere, le mokhoa o sebetsang oa ts'ebetso.E fa bareki lits'ebeletso tsa ho fetola CNC tsa boleng bo holimo le tse sebetsang ka theko ea tlholisano, hape e fetola lits'oants'o tse hlakileng tsa boenjiniere hore e be likarolo tse fapaneng tse nepahetseng.

Mokhoa o ikhethileng oa likarolo tsa lathe

Litlhoko tse nepahetseng bakeng sa Likarolo tse Fetohang tse Tloaelehileng

| Ho nepahala ha mochini | |

| ka kakaretso e ka fihlela litlhoko | |

| ho nepahala ha mochini | ± 0.005 MM |

| (√) | Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

| Mini Order Palo(MOQ)≥1 | |

Machining Ka tloaelo Sebelisoa Thepa & Surface Treatment

Likarolo tse fapaneng tse nepahetseng li ka sebelisa lisebelisoa tse fapaneng ho latela litlhoko tsa moralo oa sehlahisoa.Re ka sebetsana le lisebelisoa tse fapaneng le kalafo ea bokaholimo ho fihlela litlhoko tsa bareki.Lisebelisoa tse tloaelehileng le phekolo ea holim'a metsi ke tse latelang:

| Lisebelisoa tse tloaelehileng & kalafo ea holim'a metsi | ||

| Tloaelehileng Lisebelisoa | Tšepe | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Kr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, etc. | ||

| Aluminium | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, etc. | ||

| Ts'epe e sa beng le mabali | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H, ,SUS316, SUS316L, Tlhaloso: SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, etc. | ||

| Koporo | T2, TU1/2, TP1/2, ,Koporo, Koporo, Boronse, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, etc. | ||

| Plastiki | PEKE, PEEK1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, PET, PET+30%GF, PC, PC+30%GF, Nylon, ABS, ESD225/420/520, etc. | ||

| Phekolo ea bokaholimo | Tlosa Anodize, Anodize e ntšo, Bothata ba Anodize, Blue / Red Anodize, Chromate Plating, QPQ | |

| Nickel e se nang Motlakase/Nine/Chromium Plate, Black oxide, Silver\Golden plating, Lehlabathe, DLC | ||

| Orbital Sanded, Passivated, TIN PlatingTungsten Carbide Coating, Ho roala ha polyurethae, etc. | ||