Litšebeletso tsa Machining tsa 5 Axis CNC

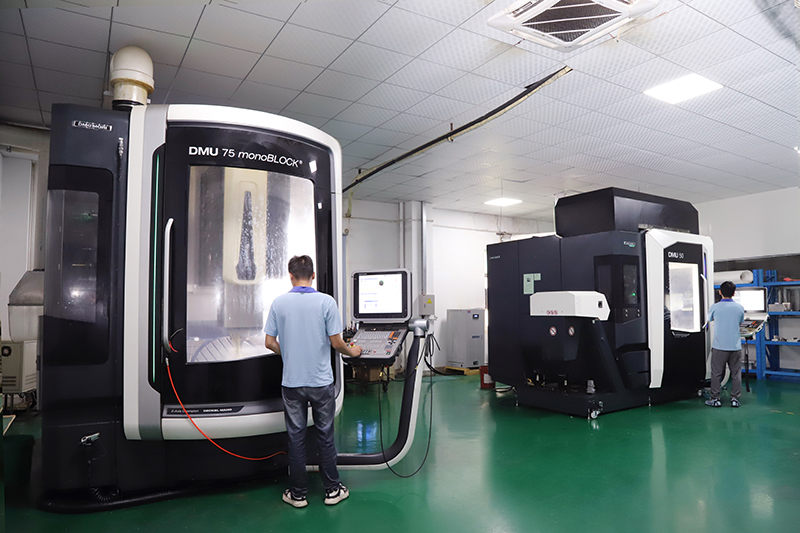

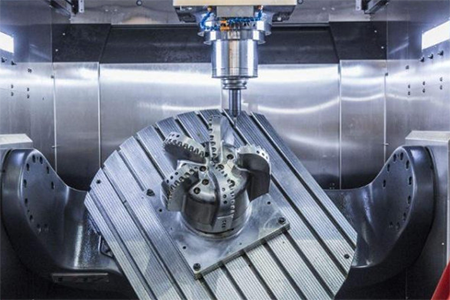

K-TEK e hlahisitse mochine oa lefats'e oa ultra precision-DMG 5-Axis Machining Center ho tloha 2018 e le ho finyella litlhoko tse phahameng liindastering tse fapaneng. hammoho le A le B, eo sesebelisoa se potolohang ho eona.Ho sebelisa mochini oa 5-axis CNC ho etsa hore basebelisi ba atamele karolo ho tsoa nqa tsohle ts'ebetsong e le 'ngoe, ho tlosa tlhoko ea ho beha sebaka sa mosebetsi pakeng tsa ts'ebetso.5-axis CNC machining e boloka nako mme e loketse ho theha likarolo tse rarahaneng le tse nepahetseng joalo ka tse fumanoang indastering ea oli le khase ea bongaka, le liindasteri tsa sefofane.Indexed 5-axis machining e ntle bakeng sa ho etsa sepakapaka, sebopeho se ikhethileng, sekoti, ho phunya, lesoba le oblique le seha se oblique.

± 0.005MM

(√)Ra0.2

Melemo ea 5-axis machining

1.Ho nepahala ho phahameng le katleho e potlakileng

5-axis machining e na le ho nepahala ho phahameng le ho sebetsa ka potlako.E ke ke ea phethela feela mesebetsi ea ts'ebetso ea likarolo tse fapaneng tse kopaneng tse tsoang lihlahisoa tse fapaneng tsa indasteri, empa hape e fokotsa linako tsa ho koala le ho phalla ha thepa hammoho le ho laola boleng ba sehlahisoa hantle, e leng se re thusang ho boloka litšenyehelo tse ngata le ho etsa hore re be le tlhōlisano. likarolo li hloka ho sebetsana le libaka tse ngata 'me 5-axis e ka fihlela litlhoko tsena tsa ts'ebetso ka ho boloka nako e ngata, ho fokotsa potoloho ea tlhahiso le ho qeta kapele ho fana ka bareki.

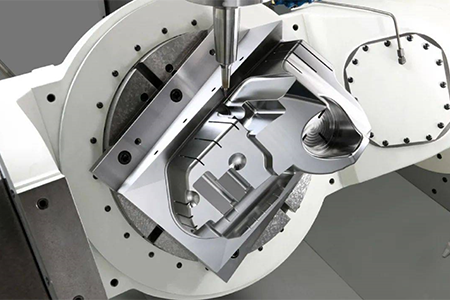

2.Ntlafatsa ho nepahala le ho sebetsa ka nepo

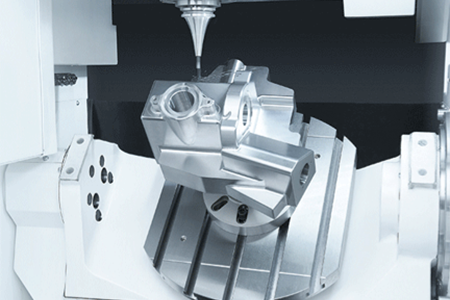

Hase feela hore mefuta ena ea mechine e silang ea 5-axis CNC e fana ka ho nepahala ho hoholo ha ho etsoa likarolo tse tebileng le lisebelisoa tse thata, empa hape li fana ka lihlahisoa tse phahameng le lebelo la ho sebetsa ka potlako.Leha ho le joalo, machining a 5-axis a theko e boima haholo ka lebaka la lisebelisoa tse khethehileng tse hlokahalang le tlhoko ea basebetsi ba litsebi.

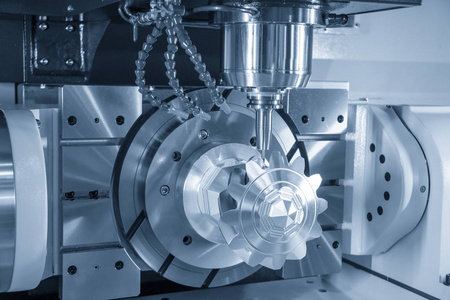

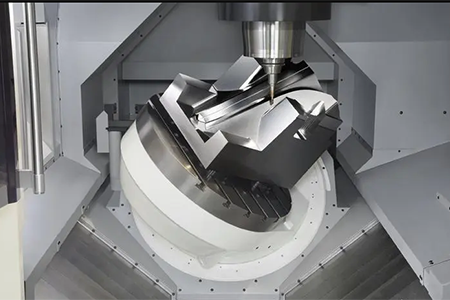

Ka theknoloji ea machining ea 5-axis, bothata ba ho nepahala ha makhetlo a mangata a li-workpieces tse nang le li-angles tse rarahaneng bo rarolloa.Hase feela hore nako e khutsufalitsoe, empa mamello e nyane ea machining e rarollotsoe hantle.5-axis machining e ka sebetsana le likarolo tse rarahaneng, tse kang ho cheka, ho sebetsa ka taper, li-cavities le li-grooves tse nang le libaka tse rarahaneng tse kobehileng, joalo-joalo, tse ke keng tsa finyelloa ka mekhoa ea setso ea ho sebetsa maemong a mangata.

3. Qetello ea boleng bo phahameng

5-Axis machining e boetse e thusa ho theha bokaholimo bo nang le pheletso ea boleng bo holimo.Likarolo li behiloe haufi le lisebelisoa tsa ho itšeha ka har'a mochini oa 5-axis, o sa sisinyeheng haholo, o fellang ka pheletso ea boleng bo holimo.ho nepahala ha ts'ebetso ho ka laoloa ka hare ho ± 0.002MM, taolo ea holim'a metsi (√) ho Ra0.2.

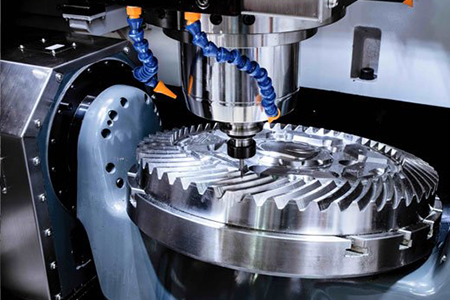

4.Ho sebetsa ka mokhoa o phahameng

5-axis machining e ka fokotsa ka nepo nako ea ts'ebetso le nako e thusang ea likarolo.E na le lebelo le leholo la spindle le mefuta ea lijo, e le hore mochine o be le bokhoni bo matla ba ho itšeha.Motsamao o potlakileng le boemo ba machining a li-axis tse hlano le machining a ho seha ka lebelo le phahameng li thusa ho fokotsa nako ea ho fetola lihlahisoa tse felileng le ho ntlafatsa katleho ea tlhahiso le ho nepahala.Ha re tobane le mefuta e mengata e rarahaneng ea likarolo tse sebetsang hantle ho re fa litharollo tse sebetsang tsa tlhahiso, athe ts'ebetso le boleng bo boetse bo tlisitse ntlafatso e kholo, ka lits'ebeletso tsa ho sila tsa CNC ho moralo oa sehlahisoa sa bareki kapa mehopolo ho ba 'nete, thepa e kenyelletsang mefuta e fapaneng ea tšepe le polasetiki. le mefuta e fapaneng ea phekolo ea holim'a metsi.

Lilemo tse 10+ tsa Boiphihlelo ba 5-Axis Cnc Machining le Sehlopha sa Boenjiniere

Khopolo:Lihora tse 3 tsa quote, lihora tse 5 ho etsa litšebeletso tsa tharollo ea ho khoneha le keletso.

Boenjiniere le Moralo:E lokolohile ho thusa bareki ho ntlafatsa sebopeho sa sehlahisoa le ho rala litšoantšo tsa 3D.

Meetso e Tloaelehileng:Etsa likarolo life kapa life tse rarahaneng tsa 5-axis CNC tse ipapisitseng le litšoantšo le lisampole tsa bareki.

Katleho:Fektheri e na le lisebelisoa tse feletseng, 'me mekhoa e fapaneng ea mechine ea CNC e kopantsoe ho ntlafatsa ts'ebetso ea ts'ebetso le ho qeta ho fana ka kapele.

Mohlala oa Thomello:Fana ka lisampole ka beke e le 'ngoe, tlaleha mathata a sampole, 'me u etse hore tlhahiso e ngata e be bonolo.

Netefaletso ea boleng:Mosebetsi o mong le o mong o feta ka mokhoa o thata oa tlhahlobo ea boleng.Sesebelisoa sa ho hlahloba se kenyelletsa sesebelisoa sa ho lekanya sa 3D CMM, altimeter, quadratic element, joalo-joalo Ho tloha tlhahlobo ea pele ea boenjiniere DFM, pre-production, IQC, sehlooho sa pele, mokhoa oa ho etsa tlhahiso ho fihlela tlhahlobo ea ho qetela, re laola ka thata boleng ho netefatsa boleng.Litekanyetso tse ntlafalitsoeng tsa tlhahiso li u fa likarolo tsa machining tsa 5-axis CNC tse nang le sekhahla se nepahetseng sa ho feta se fihlang ho 99%.

Tšebeletso ea Boleng:Ts'ebetso e 'ngoe le e' ngoe ea tlhahiso e ngotsoe hantle 'me e arolelanoa pepeneneng le moreki.

5 Axis CNC Machining Lisebelisoa tse sebelisoang hangata

5-axis CNC e ka sebetsana le lisebelisoa tse fapaneng, haeba u sa tsebe ho khetha thepa e nepahetseng, baenjiniere ba rona ba ka boela ba u khothaletsa thepa e nepahetseng ho latela litlhoko tsa hau tsa tlhahiso le ts'ebetso ea likarolo tsa mochini tsa 5-axis CNC.Tse latelang ke lisebelisoa tsa rona tse sebelisoang hangata, re ka boela ra sebetsana le lisebelisoa tse ling ho latela litlhoko tsa bareki.

| Lisebelisoa tse tloaelehileng & kalafo ea holim'a metsi | ||

| Tloaelehileng Lisebelisoa | Tšepe | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Kr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, etc. | ||

| Aluminium | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, etc. | ||

| Ts'epe e sa beng le mabali | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H, ,SUS316, SUS316L, Tlhaloso: SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, etc. | ||

| Koporo | T2, TU1/2, TP1/2, ,Koporo, Koporo, Boronse, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, etc. | ||

| Plastiki | PEKE, PEEK1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, PET, PET+30%GF, PC, PC+30%GF, Nylon, ABS, ESD225/420/520, etc. | ||

| Phekolo ea bokaholimo | Tlosa Anodize, Anodize e ntšo, Bothata ba Anodize, Blue / Red Anodize, Chromate Plating, QPQ | |

| Nickel e se nang Motlakase/Nine/Chromium Plate, Black oxide, Silver\Golden plating, Lehlabathe, DLC | ||

| Orbital Sanded, Passivated, TIN PlatingTungsten Carbide Coating, Ho roala ha polyurethae, etc. | ||

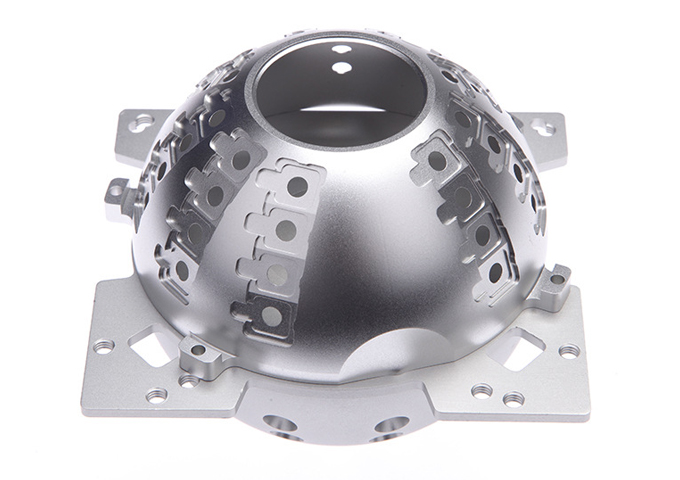

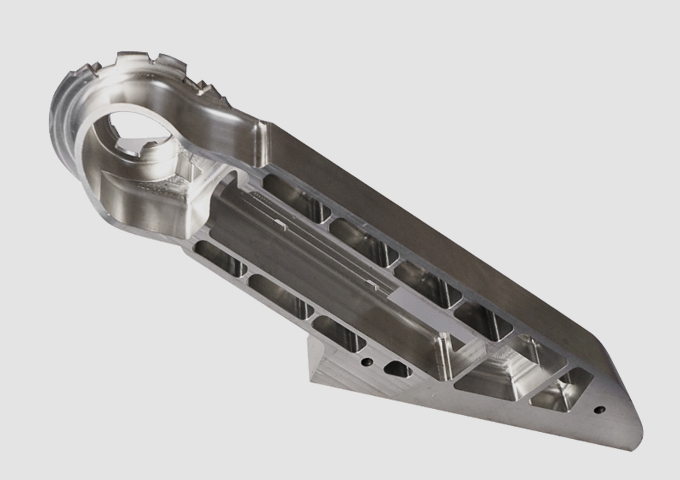

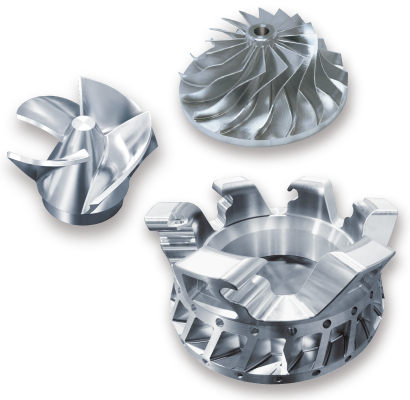

Pontšo ea Nyeoe

K-Tek e sebetsana haholo le ts'ebetso ea tloaelo ea likarolo tse ngata tse fapaneng le tse nyane, likarolo tsohle li etsoa ho latela litlhoko tsa bareki.Mona ke tse ling tsa linyeoe tseo re li hlahisitseng pele:

Lihlahisoa tsa lihlahisoa tsa aluminium

Likarolo tsa ho sebetsa lihlahisoa tsa tšepe

Likarolo tsa ho sebetsa lihlahisoa tsa tšepe e sa hloekang

Likarolo tsa ho lokisa lihlahisoa tsa koporo le tsa polasetiki