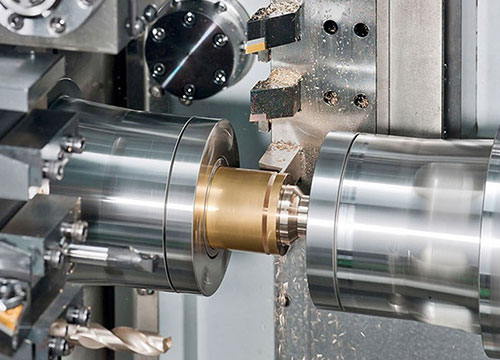

Adeegyada leexinta CNC

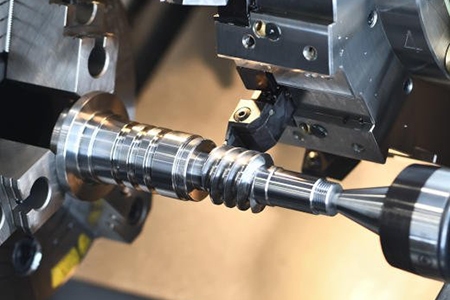

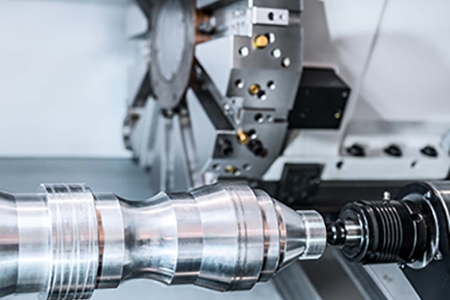

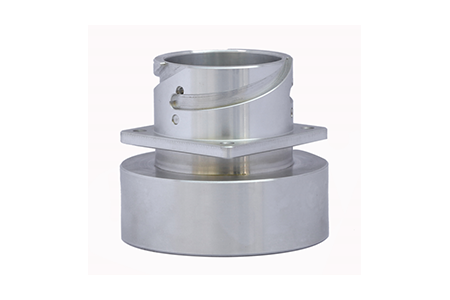

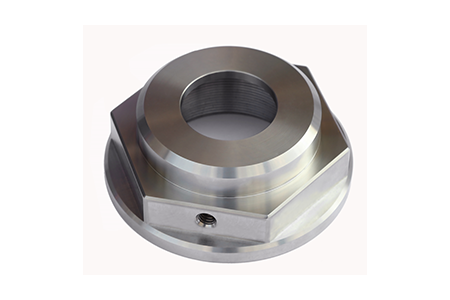

Dareenka CNC waxaa inta badan loo isticmaalaa in lagu gooyo gudaha iyo dibadda sagxadaha cylindrical ee qaybaha usheeda dhexe ama qaybaha diskka, gudaha iyo dibadda dusha koontada xaglo koorta, qaloocin adag gudaha iyo dibadda dusha, dhululubada, dunta tol, iwm. barnaamijka processing, waxay ka baaraandegi kartaa qaybaha saxda ah sida jeexdin, qodista, reaming, reaming iyo caajis.

±0.005MM (√)Ra0.2

Mashiinka CNC wuxuu leeyahay sifooyinka soo socda

● Saxnaanta hab-socodka sare iyo tayada habaynta deggan;

● Waxay fulin kartaa isku xirka isku-duwayaasha badan, heer sare oo otomaatig ah, waxayna farsamayn kartaa qaybo leh qaabab adag;

● Marka la bedelayo qaybaha wax soo saarka, guud ahaan waxay u baahan yihiin oo kaliya in la beddelo barnaamijka NC, kaas oo badbaadin kara wakhtiga diyaarinta wax soo saarka iyo hagaajinta waxtarka;

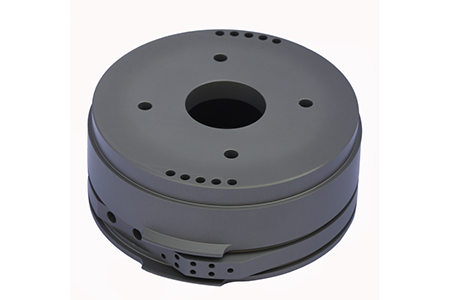

Qaybaha Mashiinnada Saxda ah ee Tayada Sare La Dammaanad qaaday

K-TEK waxay leedahay qalab farsamayn oo heersare ah, koox injineernimo oo heer sare ah, iyo hab hawleed hufan.Waxay siisaa macaamiisha adeegyo rogid CNC tayo sare leh oo hufan qiimo tartan leh, waxayna u beddeshaa naqshadaynta naqshadaynta injineernimada qaybo kala duwan oo sax ah.

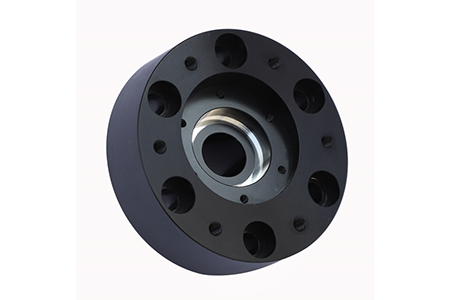

Mashiinka gaarka ah ee qaybaha lathe

Shuruudaha Saxda ah ee Qaybaha Wareega Gaarka ah

| Saxnaanta mashiinka | |

| guud ahaan buuxin kara shuruudaha | |

| saxnaanta mashiinka | ± 0.005 MM |

| (√) | Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

| Tirada Dalabka Yar(MOQ)≥1 | |

Makiinada Alaabta Caadiga Ah Loo Isticmaalo & Daawaynta Dusha Sare

Qaybaha kala duwan ee saxda ah waxay isticmaali karaan walxo kala duwan iyadoo loo eegayo shuruudaha naqshadeynta alaabta.Waxaan ka baaraandegi karnaa agab kala duwan iyo daawaynta dusha sare si aan u daboolno shuruudaha macaamiisha.Qalabka caadiga ah iyo daaweynta dusha sare waa sida soo socota:

| Agabka caadiga ah & daawaynta dusha sare | ||

| Caadiyan Qalabka | Birta | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, iwm. | ||

| Aluminium | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, iwm. | ||

| Bir daxal laheyn | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H,SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, iwm. | ||

| Copper | T2, TU1/2, TP1/2,Naxaas, Copper, Bronze, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, iwm. | ||

| caag | DAAWO, 1000 PEEK, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30% GF, PBT, PET, PET+30% GF, PC, PC+30% GF, Nayloon, ABS, ESD225/420/520, iwm. | ||

| Daaweynta dusha sare | Nadiifi Anodize, Black Anodize, Adag Anodize, Anodize buluug/cas, Dusha sare ee Chromate, QPQ | |

| Nikkel/Sagaal/Chromium Plate oo aan koronto lahayn, Black Oxide, Silver\Dahab dahab ah, Bacaad lagu lisay, DLC | ||

| Orbital Sanded, Baasoobay, Dahaarka TIN Plating Tungsten Carbide Dahaarka, Dahaarka polyurethae, iwm. | ||