5 Axis CNC Machining Services

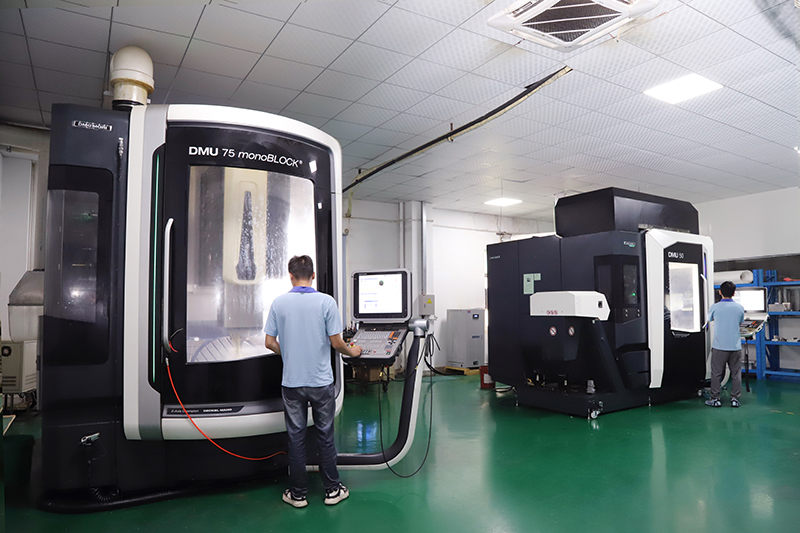

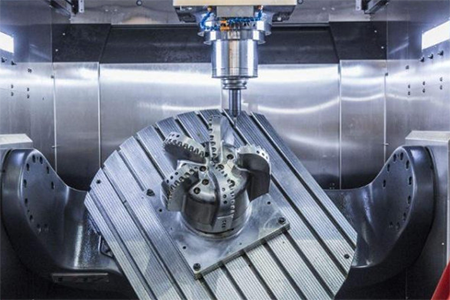

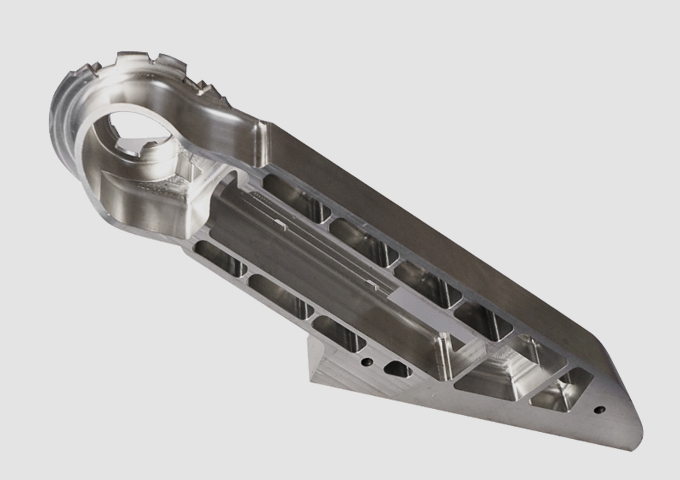

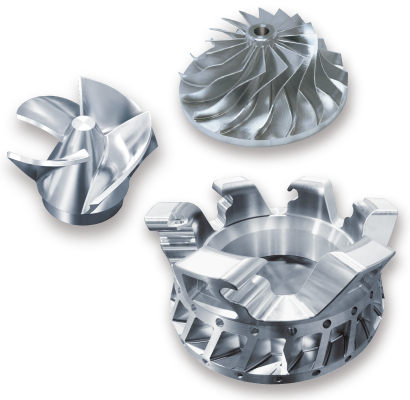

K-TEK waxay soo bandhigtay mashiinka saxda ah ee saxda ah ee aduunka-DMG 5-Axis Machining Center tan iyo 2018 si loo buuxiyo shuruudaha sare ee warshadaha kala duwan. iyo sidoo kale A iyo B, oo ku wareegsan qalabku wareego.Isticmaalka mashiinka CNC ee 5-dhidibka ah ayaa u ogolaanaya hawl-wadeenadu inay u dhawaadaan qayb ka mid ah jihooyinka oo dhan hal hawlgal, iyaga oo meesha ka saaraya baahida loo qabo in gacanta lagu beddelo qaybta shaqada ee u dhaxaysa hawlgallada.5-axis CNC machining waxay badbaadisaa waqti waxayna ku habboon tahay abuurista qaybo adag oo sax ah sida kuwa laga helo saliidda iyo gaaska caafimaadka, iyo warshadaha hawada sare.Mashiinka 5-dhidibka ah ee la tilmaansaday wuxuu ku fiican yahay soosaarka dusha bannaan, qaab-gaar ah, dalool, feeray, dalool qarda-jeex ah iyo goyn qarda-jeex ah.

±0.005MM

(√)Ra0.2

Faa'iidooyinka mashiinka 5-axis

1. Saxnaanta sare iyo waxtarka degdega ah

Mashiinka dhidibka 5 wuxuu leeyahay saxnaanta sare iyo waxtarka degdega ah.Ma aha oo kaliya dhamaystirka hawlaha processing ee qaybo kala duwan oo isku dhafan oo ka soo baxa alaabooyinka kala duwan ee warshadaha, laakiin sidoo kale waxay yareeyaan waqtiyada xajinta iyo socodka socodsiinta iyo sidoo kale xakamaynta tayada alaabta si fiican, taas oo naga caawinaysa inaan badbaadino kharash badan oo naga dhigaya mid aad u tartan badan. Qaybaha waxay u baahan yihiin inay ka baaraandegaan sagxadaha badan iyo dhidibka 5-aad waxay gaari karaan shuruudahan farsamaynta iyadoo la badbaadinayo waqti badan, yaraynta wareegga wax-soo-saarka iyo si dhakhso ah u dhamaystiraya bixinta macaamiisha.

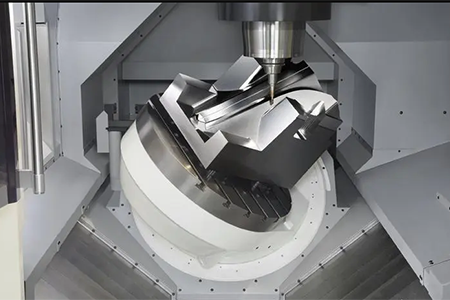

2.Hagaajinta saxnaanta iyo habaynta saxnaanta

Kaliya maahan noocyadan 5-axis ee mishiinnada wax-shiidka ee CNC waxay bixiyaan saxsanaan weyn marka la farsameynayo qaybo qoto dheer iyo agab adag, laakiin sidoo kale waxay bixiyaan wax soo saar sare iyo xawaare farsamayn.Si kastaba ha ahaatee, mashiinka 5-axis ayaa aad qaali u ah sababtoo ah qalabka gaarka ah ee lagama maarmaanka ah iyo baahida shaqaale khabiiro ah.

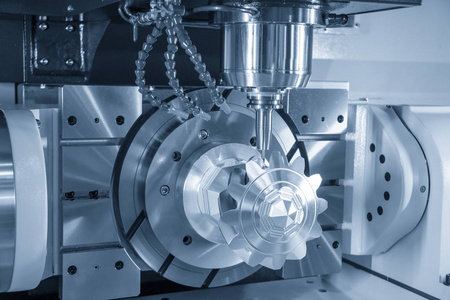

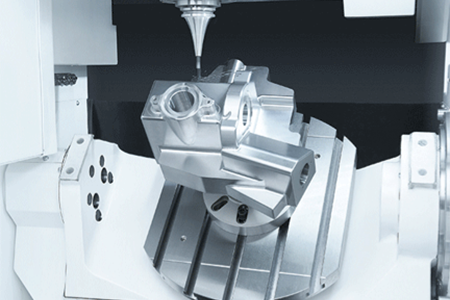

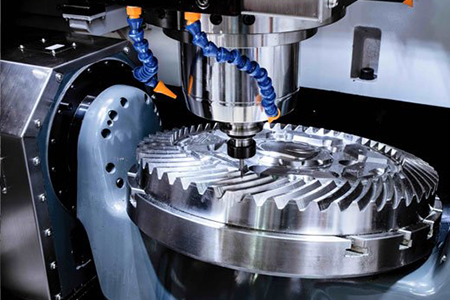

Iyada oo loo marayo tignoolajiyada mishiinada dhidibka 5-dhidibka ah, mushkilada saxnaanta meelaynta badan ee qaybaha shaqada ee leh xaglo adag ayaa la xalliyaa.Ma aha oo kaliya in waqtiga la soo gaabiyay, laakiin mashiinada dulqaadka khafiifka ah ayaa si wanaagsan loo xaliyay.Mashiinka dhidibka 5-aad waxa uu farsamayn karaa qaybo kakan, sida qodista, farsamaynta taper-ka, godadka iyo godadka leh sagxadaha qaloocan, iwm, kuwaas oo aan lagu gaadhi karin hababka hab-dhaqameedka inta badan.

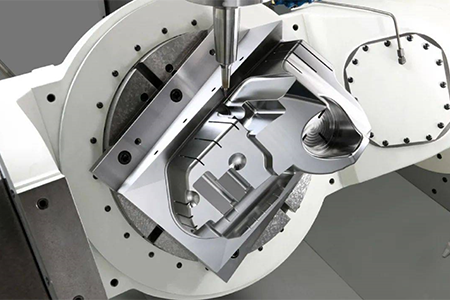

3. Dhamaystir tayo sare leh

5-Machining axis sidoo kale waxay caawisaa abuurista sagxadaha oo leh dhamaystir tayo sare leh.Qaybaha waxaa lagu meeleeyaa meel u dhow qalabka wax lagu gooyo ee mashiinka 5-axis, kuwaas oo aan gariirin wax badan, taasoo keentay dhamaystir tayo sare leh.saxnaanta farsamaynta waxaa lagu xakameyn karaa gudaha ± 0.002MM, xakamaynta dusha sare (√) ee Ra0.2.

4.High processing waxtarka

Mashiinka dhidibka 5-aad wuxuu si wax ku ool ah u dhimi karaa waqtiga wax-qabadka iyo waqtiga kaalmaynta ee qaybaha.Waxay leedahay xawaarihii dunnida iyo quudinta ballaaran, si mashiinku u yeesho awood goyn oo weyn.Dhaqdhaqaaqa degdega ah iyo meelaynta mashiinnada shanta dhidibka ah iyo mashiinnada goynta xawaaraha sare leh waxay gacan ka geystaan yaraynta waqtiga soo-jeedinta ee alaabada dhammaatay iyo hagaajinta wax-soo-saarka iyo saxnaanta.Marka la eego noocyo kala duwan oo ka mid ah qaybaha saxda ah ee saxda ah ee qallafsan si ay noo siiyaan xalal wax soo saar wax ku ool ah, halka hufnaanta iyo tayada ay sidoo kale keentay horumar weyn, iyada oo loo marayo adeegyada wax-shiidka CNC macaamiisha naqshadeynta alaabta ama fikradaha dhabta ah, qalabka ku lug leh noocyo kala duwan oo biraha iyo balaastikada ah. iyo noocyo kala duwan oo daaweynta dusha ah.

10+ sano oo 5-Axis Cnc Machining Khibrad iyo Kooxda Injineerinka

Xigasho:Xigasho 3 saacadood ah, 5 saacadood oo wax soo saar ah oo xal u helida adeegga iyo talada.

Injineernimada iyo Naqshadeynta:Xor u ah in lagu caawiyo macaamiisha si ay u wanaajiyaan qaab dhismeedka alaabta iyo naqshadeynta sawirada 3D.

Nashqadaha Gaarka ah:Soo saar wax kasta oo sax ah oo adag oo 5-dhidib ah oo CNC ah oo lagu farsameeyay qaybo ka mid ah sawirada macaamiisha iyo muunadaha.

WaxtarkaWarshadu waxay si buuxda ugu qalabaysan tahay qalab, iyo habab kala duwan oo mashiinada CNC ayaa la isku daray si loo hagaajiyo waxtarka habaynta iyo si dhakhso ah u dhamaystirto bixinta.

Tusaalaha Gaarsiinta:Keen muunado hal toddobaad gudaheed ah, diiwaan geli dhibaatooyinka muunadda, oo ka dhig wax-soo-saarka tirada badan.

Xaqiijinta Tayada:Shaqo kastaa waxay martaa hab imtixaan tayo adag leh.Qalabka kormeerka waxaa ku jira 3D CMM qalabka cabbiraadda, altimeter, element quadratic, iwm. Laga soo bilaabo dib u eegista injineernimada bilowga ah DFM, wax soo saarka hore, IQC, maqaalka koowaad, habka wax soo saarka ilaa kormeerka kama dambaysta ah, waxaanu si adag u xakameynaa tayada si loo hubiyo tayada.Heerarka wax soo saarka ee la safeeyey ayaa ku siinaya 5-dhidib CNC qaybo mashiineed leh heerka gudbinta saxda ah ee ilaa 99%.

Adeeg Tayo leh:Dhaqdhaqaaq kasta oo wax soo saar si wanaagsan ayaa loo diiwaangeliyay oo si hufan loola wadaagaa macaamilka.

5 Axis CNC Machining Alaabta Inta Badan La Isticmaalo

5-axis CNC waxay farsameyn kartaa noocyo kala duwan oo qalab ah, haddii aadan aqoon sida loo doorto qalabka saxda ah, injineeradayadu waxay sidoo kale kugula talinayaan qalabka saxda ah ee adiga ku habboon baahidaada wax soo saarka iyo waxqabadka qaybaha 5-axis ee CNC.Kuwa soo socda waa agabka habaynta ee inta badan la isticmaalo, waxaan sidoo kale u habayn karnaa agabka kale iyadoo loo eegayo baahida macaamiisha.

| Agabka caadiga ah & daawaynta dusha sare | ||

| Caadiyan Qalabka | Birta | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, iwm. | ||

| Aluminium | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, iwm. | ||

| Bir daxal laheyn | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H,SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, iwm. | ||

| Copper | T2, TU1/2, TP1/2,Naxaas, Copper, Bronze, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, iwm. | ||

| caag | DAAWO, 1000 PEEK, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30% GF, PBT, PET, PET+30% GF, PC, PC+30% GF, Nayloon, ABS, ESD225/420/520, iwm. | ||

| Daaweynta dusha sare | Nadiifi Anodize, Black Anodize, Adag Anodize, Anodize buluug/cas, Dusha sare ee Chromate, QPQ | |

| Nikkel/Sagaal/Chromium Plate oo aan koronto lahayn, Black Oxide, Silver\Dahab dahab ah, Bacaad lagu lisay, DLC | ||

| Orbital Sanded, Baasoobay, Dahaarka TIN Plating Tungsten Carbide Dahaarka, Dahaarka polyurethae, iwm. | ||

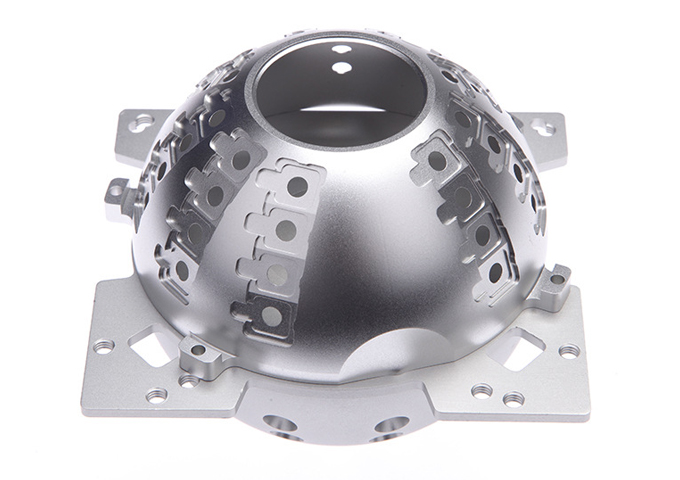

Bandhig Kiis

K-Tek inta badan waxay ku hawlan tahay habaynta caadada ee qaybo badan oo kala duwan iyo qaybo yar yar oo makaanik ah, dhammaan qaybaha waxaa loo sameeyaa iyadoo loo eegayo baahida macaamiisha.Waa kuwan qaar ka mid ah kiisaska habaynta oo aan horay u soo saarnay:

Alaabooyinka farsamaynta aluminiumka

Qaybaha farsamaynta alaabta birta

Qaybaha farsamaynta alaabta birta ah

Copper & Qaybaha farsamaynta alaabta caaga ah