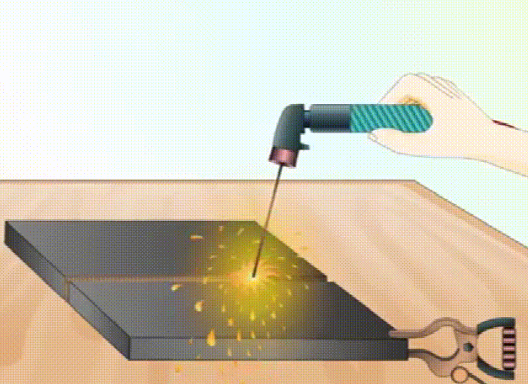

1, Electrode arc welding

Arc welding ndeimwe yehunyanzvi hwekutanga hunyanzvi hunoitwa nemawelder, kana hunyanzvi husipo, pachave nekukanganisa kwakasiyana-siyana mumusono wekushongedza.

2, Yakadzika arc welding

Submerged arc welding inzira yewelding inoshandisa arc senzvimbo yekupisa. Nekuda kwekupinda kwakadzika kwearc welding yakanyungudutswa, mhando yewelding yakanaka: nekuda kwekuchengetedzwa kweslag yakanyungudutswa, simbi yakanyunguduka haisi kusangana nemhepo, uye dhigirii rekushandisa mechanization rakakwirira, saka rakakodzera kuputika. marefu mawelds epakati uye akakora ndiro zvimiro.

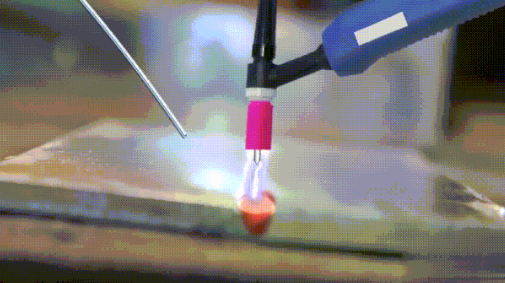

3. Argon arc welding

Heano mamwe matanho ekuchengetedza argon arc welding:

(1) Tsono yetungsten inofanira kurodzwa nguva nenguva. Kana yakagomara, iyo yazvino haizoisirwe uye iyo welding ichapedzwa.

(2) Kana chinhambwe chiri pakati petsono yetungsten uye weld iri padhuze zvakanyanya, zvinonamatira pamwechete. Kana iri kure, arc inotumbuka. Kana arc yatumbuka, ichapisa dema uye tsono yetungsten ichaita mhanza. Mwaranzi kune wega yakasimbawo. Zviri nani kuichengeta pedyo.

(3) Kudzora kwe switch ihunyanzvi, kunyanya kune yakatetepa plate welding. Inogona chete kubatidzwa rimwe nerimwe. Uyu hausi we otomatiki welding muchina une otomatiki kufamba uye otomatiki waya yekudyisa. Kana ikaramba ichitsva, ichasakara.

(4) Unoda kudyisa waya. Izvi zvinoda pfungwa yekubata. Welding yemhando yepamusoro inochekwa kubva pamahwendefa mazana matatu nemana nemuchina wekugera. Usazvitenga mumasumbu. Ehe, unogona kuwana dzakanaka paholesale.

(5) Edza kushanda munzvimbo ine mhepo inofefetera, pfeka magirovhosi ematehwe, zvipfeko, uye masiki anozviitira dimming.

(6) Musoro weceramic wepfuti yekuputika inofanira kudzivirirwa kubva kune arc. Kunyanya, muswe wepfuti yewelding unofanirwa kunanga kuchiso chako zvakanyanya sezvinobvira.

(7) Kana iwe uchigona kuve neruzivo uye kufungidzira nezve tembiricha, saizi, uye chiito chedziva rakanyungudutswa, iwe uri nyanzvi yepamusoro.

(8) Edza kushandisa tsono dzetungsten dzine mavara eyero kana machena, sezvo izvi zvinoda hunyanzvi hwepamusoro.

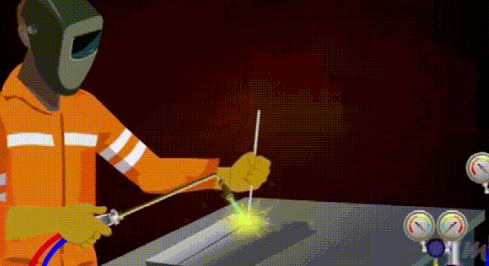

4. Oxygen fuel gasi welding

Oxygen fuel gasi welding ndiko kushandiswa kwemurazvo kupisa simbi uye welding waya pamubatanidzwa wesimbi workpieces kunyungudusa uye kuzadzisa chinangwa chewelding. Magasi anopisa anowanzo shandiswa zvikuru acetylene, liquefied petroleum gas nehydrogen, uye gasi rinopisa rinowanzo shandiswa iokisijeni.

5. Laser welding

Laser welding inzira inoshanda uye chaiyo yewelding inoshandisa yakakwirira-simba-density laser beam sechinhu chekupisa. Laser welding ndechimwe chezvinhu zvakakosha zvekushandiswa kwelaser material processing technology. Mumakore ekuma1970, yainyanya kushandiswa kugadzira simbi dzakatetepa-madziro uye yakaderera-kumhanya welding. Iyo welding process imhando yekupisa yekupisa, kureva kuti, laser mwaranzi inopisa pamusoro peiyo workpiece, uye kupisa kwepamusoro kunopararira mukati kuburikidza nekupisa conduction. Nekudzora hupamhi, simba, simba repamusoro uye kudzokorora frequency ye laser pulse, workpiece inonyungudutswa kuita dziva rakanyungudutswa.

Nguva yekutumira: Oct-22-2024