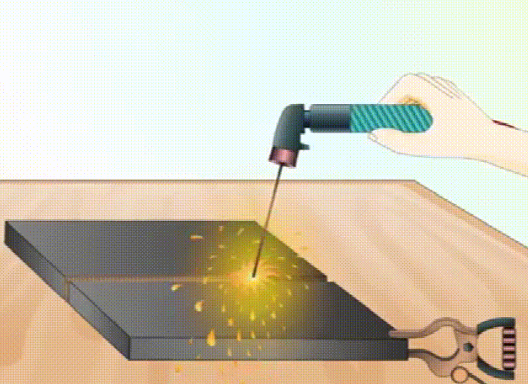

1, Electrode arc kuwotcherera

Kuwotcherera kwa Arc ndi imodzi mwamaluso ofunikira kwambiri omwe ma welder amawadziwa, ngati luso silili m'malo, padzakhala zolakwika zosiyanasiyana mumsoko wowotcherera.

2, kuwotcherera arc pansi pamadzi

Kuwotcherera kwa arc ndi njira yowotcherera pogwiritsa ntchito arc ngati gwero la kutentha. Chifukwa cha kulowera kwakuya kwa kuwotcherera kwa arc pansi pamadzi, kuwotcherera kwabwino ndikwabwino: chifukwa cha chitetezo cha slag yosungunuka, chitsulo chosungunuka sichimakhudzana ndi mpweya, ndipo kuchuluka kwa makina opangira makina ndikokwera, kotero ndikoyenera kuwotcherera. zowotcherera zazitali za mbale zapakatikati ndi zokhuthala.

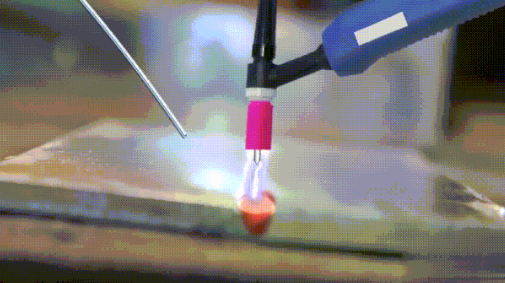

3. Kuwotcherera kwa Argon arc

Nawa njira zopewera kuwotcherera argon arc:

(1) Singano ya tungsten iyenera kunoledwa pafupipafupi. Ngati ili yosamveka, mphamvu yapano siidzakhazikika ndipo kuwotcherera kudzatha.

(2) Ngati mtunda wa pakati pa singano ya tungsten ndi chowotcherera uli pafupi kwambiri, zimamatirana. Ngati ili kutali kwambiri, arc idzaphuka. Arc ikaphuka, imayaka yakuda ndipo singano ya tungsten imakhala yadazi. Ma radiation kwa iwe mwini amakhalanso amphamvu. Ndi bwino kukhala pafupi.

(3) Kuwongolera kwa switch ndi luso, makamaka pakuwotcherera mbale zopyapyala. Itha kungoyatsidwa imodzi ndi imodzi. Awa si makina owotcherera okha omwe amangoyenda okha komanso kudyetsa waya. Ngati iyaka mosalekeza, idzatha.

(4) Umafunika kudyetsa waya. Izi zimafuna kukhudza. Waya wowotcherera wapamwamba kwambiri amadulidwa kuchokera ku mbale 304 ndi makina ometa. Osagula m'mitolo. Zachidziwikire, mutha kupeza zabwino m'malo ogulitsa.

(5) Yesetsani kugwira ntchito m'malo opumira mpweya, valani magolovesi achikopa, zovala, ndi chigoba chodziwikiratu.

(6) Mutu wa ceramic wa mfuti yowotcherera uyenera kutetezedwa ku arc. Makamaka, mchira wamfuti yowotcherera uyenera kuloza kumaso kwanu momwe mungathere.

(7) Ngati mutha kukhala ndi chidziwitso komanso chidziwitso cha kutentha, kukula, ndi machitidwe a dziwe losungunuka, ndinu katswiri wamkulu.

(8) Yesani kugwiritsa ntchito singano za tungsten zokhala ndi zolembera zachikasu kapena zoyera, chifukwa izi zimafuna luso lapamwamba.

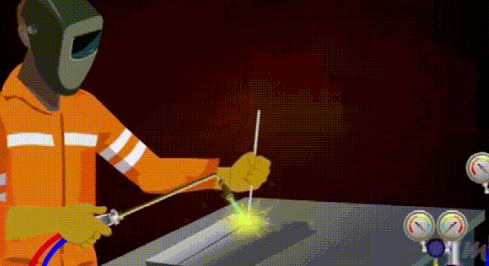

4. kuwotcherera mpweya wa okosijeni

Kuwotchera kwa mpweya wa okosijeni ndiko kugwiritsa ntchito malawi kutenthetsa zitsulo ndi waya wowotcherera polumikizana ndi zida zachitsulo kuti zisungunuke ndikukwaniritsa cholinga chowotcherera. Mipweya yoyaka yomwe imagwiritsidwa ntchito kwambiri ndi acetylene, gasi wamafuta amadzimadzi ndi haidrojeni, ndipo mpweya womwe umagwiritsidwa ntchito nthawi zambiri ndi mpweya.

5. Kuwotcherera kwa laser

Kuwotcherera kwa laser ndi njira yabwino komanso yolondola yowotcherera yomwe imagwiritsa ntchito mtanda wa laser wamphamvu kwambiri ngati gwero la kutentha. Kuwotcherera laser ndi chimodzi mwazinthu zofunika kwambiri pakugwiritsa ntchito luso laukadaulo la laser. M'zaka za m'ma 1970, ankagwiritsidwa ntchito kwambiri powotcherera zipangizo zokhala ndi mipanda yopyapyala komanso kuwotcherera otsika kwambiri. Njira yowotcherera ndi mtundu wowongolera kutentha, ndiye kuti, kuwala kwa laser kumatenthetsa pamwamba pa ntchitoyo, ndipo kutentha kwapansi kumafalikira mkati kudzera mumayendedwe a kutentha. Polamulira m'lifupi, mphamvu, mphamvu yapamwamba ndi kubwerezabwereza kwa laser pulse, workpiece imasungunuka kuti ipange dziwe losungunuka.

Nthawi yotumiza: Oct-22-2024