CNC precision machining also known as Computer Numerical Control precision machining, is a crucial process in the manufacturing industry. It involves the use of computer programs to control the movement of machinery and tools, resulting in highly accurate and precise parts and components.

In recent years, CNC precision machining has witnessed significant advancements, enabling manufacturers to produce complex and intricate products with utmost accuracy. The evolution of this technology can be attributed to various factors, including software improvements, hardware enhancements, and increased automation capabilities.

One of the most noteworthy advancements in CNC precision machining is the development of more sophisticated software programs. These programs allow manufacturers to create complex designs and simulate machining processes before they actually begin production. This enables them to identify potential issues or errors beforehand and make necessary adjustments, resulting in significant time and cost savings.

Moreover, software advancements have led to improved communication and collaboration between different departments. Engineers and designers can easily transfer their 3D models and technical specifications to the CNC machines, ensuring seamless integration and streamlining the entire manufacturing process.

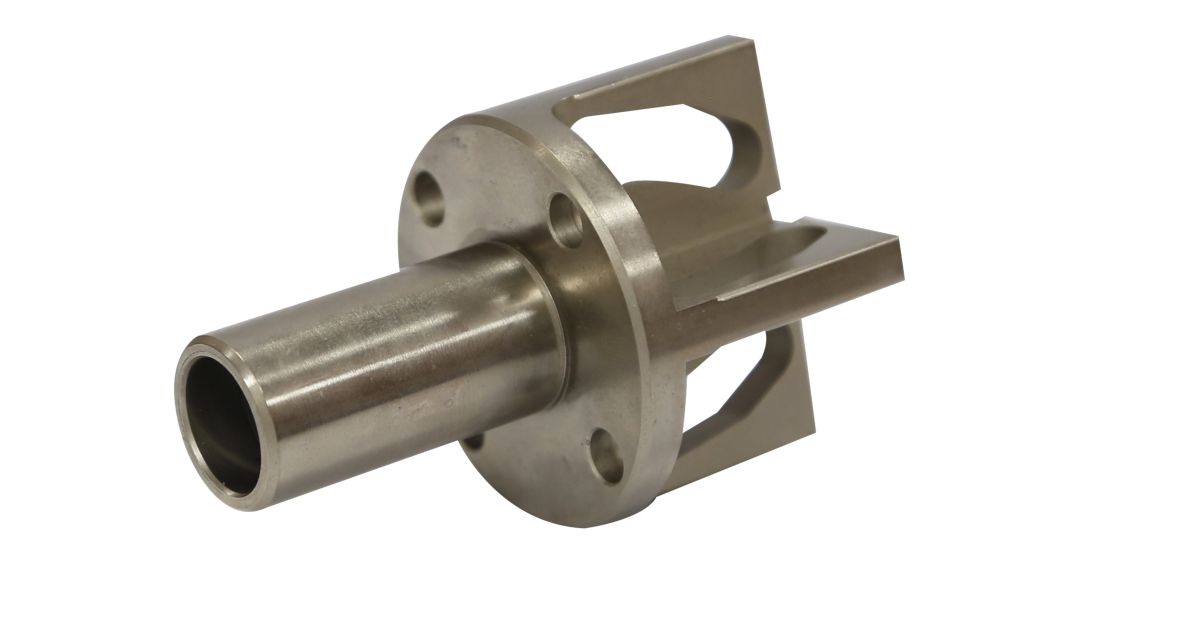

In addition to software improvements, hardware enhancements have also played a vital role in the growth of CNC precision machining. Modern CNC machines are equipped with advanced sensors, actuators, and measurement tools, which ensure precise positioning and accuracy. These machines can perform multiple operations, such as milling, drilling, and turning, in a single setup, further enhancing efficiency and reducing production time.

Automation has also been a game-changer in CNC precision machining. Automated loading and unloading systems, robotic arms, and conveyors have eliminated the need for manual intervention, ensuring consistent and reliable production. This not only reduces labor costs but also minimizes the chances of human error, leading to higher quality output.

The application of CNC precision machining is vast and spans across various industries, including aerospace, automotive, electronics, and medical. In aerospace, for example, CNC machines are used to produce complex and lightweight components, such as turbine blades and aircraft structures, with uncompromising precision.

Looking into the future, CNC precision machining is expected to continue evolving. With the rise of Industry 4.0 and the Internet of Things, CNC machines will become more interconnected, allowing for real-time monitoring, data analysis, and remote control capabilities. This will enable manufacturers to optimize their processes, reduce downtime, and make informed decisions to improve overall productivity.

In conclusion, the development of CNC precision machining has transformed the manufacturing industry. Through advancements in software, hardware, and automation, manufacturers can now produce highly accurate and intricate parts with ease. As technology continues to progress, CNC precision machining will remain at the forefront of innovation, driving efficiency, reliability, and quality in manufacturing operations.

K-tek is a 15 years professional CNC parts machining manufacturer with 200 staffs, with ISO9001-2015 certification,website www.k-tekparts.com

Our parts are used in various industries such as automotive, aerospace, medical equipment, industrial automation and more etc

If you need any CNC machining or customized parts, send the drawings to jimmy@k-tekmachining.com

Post time: Dec-02-2023