In specific applications, precision parts need to have higher precision and precision to better highlight the level of process and product quality. Moreover, such new products are more popular with customers. Overall, CNC machining has significant competitive advantages and advantages in the field of production and processing. Its product quality is usually higher, so what are the advantages of CNC machining precision parts?

CNC precision parts processing has several characteristics and processing advantages:

Characteristics:

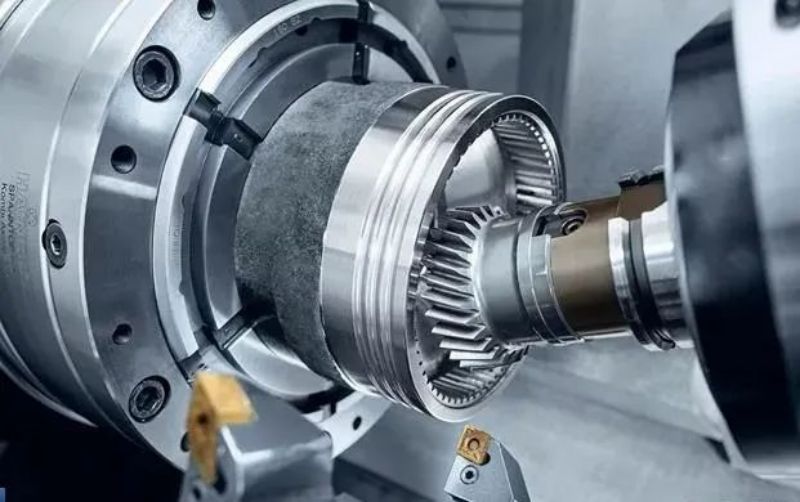

1.High precision: CNC machines can achieve extremely high levels of precision, leading to accurate and consistent parts production.

2.Versatility: Thesemachines can handle a wide range of materials, shapes, and sizes, making them suitable for diverse production needs.

3.Automation: CNC machines can be programmed to operate autonomously, reducing the need for manual intervention and increasing efficiency.

4.Complex geometries: CNC processing can fabricate intricate and complex part geometries that may be difficult to achieve using traditional methods.

Processing advantages:

1.Increased productivity:CNC machines can operate continuously, leading to higher production rates.

2.Repeatable quality: With precise programming and automated operation, CNC processing ensures consistent quality in every part.

3.Lower labor costs: Theautomation of CNC machines reduces the need for manual labor, leading to cost savings.

4.Faster production times: CNC machines can process parts at faster speeds compared to traditional machining methods.

5.Design flexibility: CNCprocessing allows for the efficient production of custom or unique parts, giving designers greater freedom in their designs.

Post time: Jan-25-2024