K-Tek company after 10 years of development, the first factory set up also encountered many difficulties, the imperfection of the various conditions, for example, we processed the imperfection of the mechanical equipment and facilities, capacity and quality will be more or less affected,, but we still hold on in the face of difficulties, because we believe that one day will do have the size of the large factory. In addition, we would like to thank our customers for their consistent support.,step by step from small factories to today's brilliant.

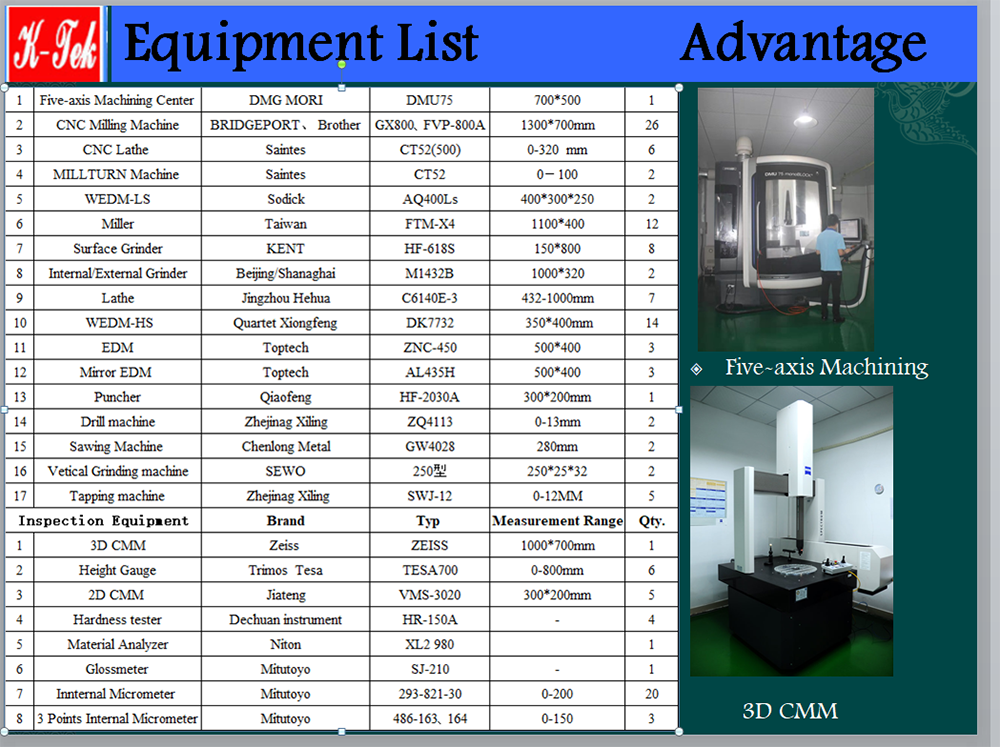

From several sets of processing equipment to more than 100 sets of advanced equipment today, our production equipment is increasing or updating every year. With the development of machining industry, machinery and equipment in various fields develop faster and faster, and the quality requirements are also higher and higher. As a factory specializing in the production of precision machinery non-standard parts, we must keep up with the technical requirements of the society, so every year from abroad to introduce a variety of advanced equipment.For example, DMG Five Axis, Zeiss 3D CMM etc.We have advanced advantages in the field of peer, we can produce a variety of machining parts can also produce sophisticated parts, the production of high-quality finished products, has been the customer's high evaluation and a steady stream of orders.

Today, our factory has introduced an advanced CNC lathe equipment from Japan. This equipment can do raw materials in and finished products out, fully automatic, which can better ensure quality and improve efficiency.,it is specialized to produce large orders, K-Tek is constantly making progress, and we are moving forward towards further goals

We can customize the production of all kinds of precision machinery parts according to the requirements of customers, products related to machinery, electronics, automation, automotive, medical, new energy and other fields. Our have passed the ISO9001:2015 certification, Our product about 20% exported to Japan, 60% product exported to Europe and America,We can off you high quality and competitive price . Our common materials are stainless steel, aluminum, copper, low carbon steel, engineering plastics and other kinds of alloy steel,Our common materials are stainless steel, aluminum, copper, low carbon steel, engineering plastics and other kinds of alloy steel, We can also provide heat treatment and various surface treatment for customers:

Our processing services include:

1) 5 Axis CNC Machining /CNC Milling/CNC Turning;

2) EDM Wire-cutting/ WEDM-HS / WEDM-LS;

3) Milling/Turning/Grinding.

Our surface treatment include:

precision metal finishing:

1.Anodize(Ordinary/Hard)

2.Electroless Nickel(Inc.Black)

3.Zinc Plating(Black/Olive/Blue/……)

4.Chemical Conversion Coating

5.Passivation(Stainless steel)

6.Chrome Plating(Inc.Hard)

7.Silver/ Golden Plating

8.Sand Blasting

9.powder spraying

10.Electro Polishing

11.Tin- Plating

12.Galvanizing

13.blackening

14.PVD etc.

welcome you to consult: sales@k-tekmachining.com tel: (+86)0769-88459539

Post time: Mar-05-2024