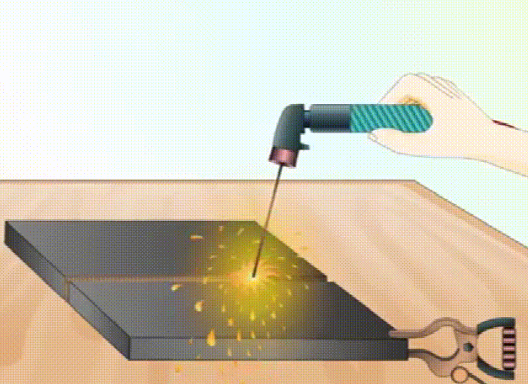

1, Electrode arc welding

Arc welding is one of the most basic skills that welders master, if the skills are not in place, there will be a variety of defects in the welding seam.

2, Submerged arc welding

Submerged arc welding is a welding method using arc as a heat source. Due to the deep penetration of submerged arc welding, the welding quality is good: because of the protection of molten slag, the melted metal is not in contact with the air, and the degree of mechanization operation is high, so it is suitable for welding long welds of medium and thick plate structures.

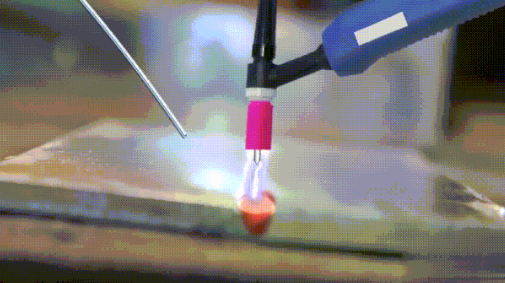

3. Argon arc welding

Here are some precautions for argon arc welding:

(1) The tungsten needle should be sharpened frequently. If it is blunt, the current will not be concentrated and the welding will be finished.

(2) If the distance between the tungsten needle and the weld is too close, they will stick together. If it is too far, the arc will bloom. Once the arc blooms, it will burn black and the tungsten needle will be bald. The radiation to the self is also strong. It is better to keep it close.

(3) The control of the switch is an art, especially for thin plate welding. It can only be turned on one by one. This is not an automatic welding machine with automatic movement and automatic wire feeding. If it burns continuously, it will wear out.

(4) You need to feed the wire. This requires a sense of touch. High-quality welding wire is cut from 304 plates with a shearing machine. Don't buy it in bundles. Of course, you can find good ones at wholesale points.

(5) Try to work in ventilated conditions, wear leather gloves, clothing, and an automatic dimming mask.

(6) The ceramic head of the welding gun should be shielded from the arc. Specifically, the tail of the welding gun should be pointed towards your face as much as possible.

(7) If you can have an intuition and premonition about the temperature, size, and action of the molten pool, you are a senior technician.

(8) Try to use tungsten needles with yellow or white markings, as this requires high craftsmanship.

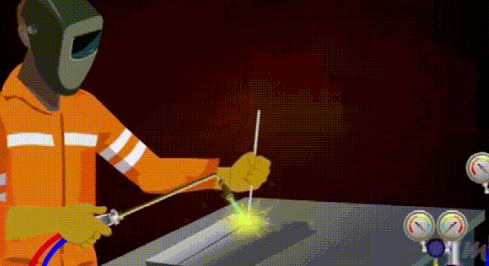

4. Oxygen fuel gas welding

Oxygen fuel gas welding is the use of flames to heat the metal and welding wire at the joint of metal workpieces to melt them and achieve the purpose of welding. Commonly used combustible gases are mainly acetylene, liquefied petroleum gas and hydrogen, and the commonly used combustion-supporting gas is oxygen.

5. Laser welding

Laser welding is an efficient and precise welding method that uses a high-energy-density laser beam as a heat source. Laser welding is one of the important aspects of the application of laser material processing technology. In the 1970s, it was mainly used for welding thin-walled materials and low-speed welding. The welding process is a heat conduction type, that is, the laser radiation heats the surface of the workpiece, and the surface heat diffuses to the inside through heat conduction. By controlling the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool.

Post time: Oct-22-2024