CNC Conversus Services

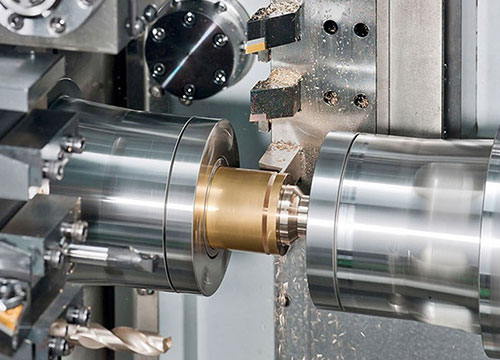

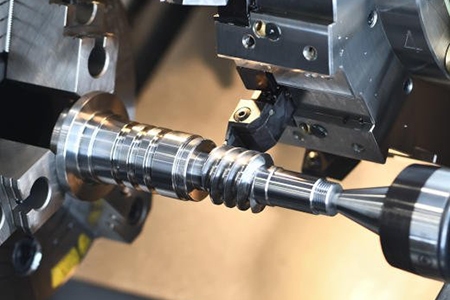

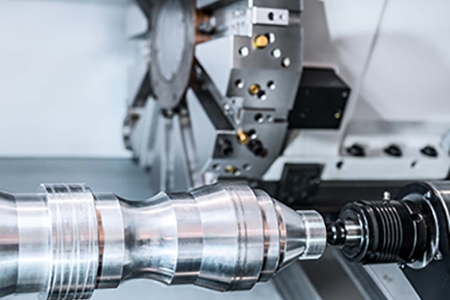

CNC Conversa praecipue adhibetur ad secandas superficies cylindricas interiores et exteriores scapi partes seu partes disci, superficies conicas interiores et exteriores angulorum arbitrarii coni, complexus gyratorius superficies curvas interiores et exteriores, cylindrici, staminum conicorum, etc. programma processus, partes praecisionis procedere potest ut sulcans, exercens, relegens, relegens et taediosus.

±0.005MM (√)Ra0.2

CNC Apparatus habet Sequentes Characteres

Princeps processus certa et stabilis processus qualitas;

Exsequi potest multi-coordinare nexum, excelsum automationis gradum, ac partes procedere cum figuris implicatis;

Cum reponatur partes processus, plerumque tantum opus est programmata NC mutare, quae praeparationem producendi tempus servare et efficaciam emendare possunt;

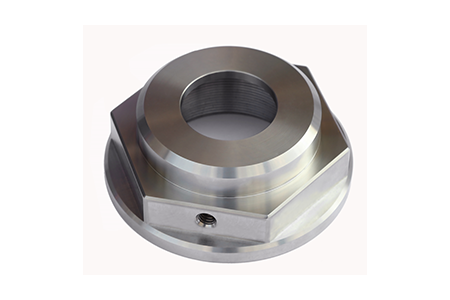

Subtilitas Machined partes High Quality Guaranteed

K-TEK processui apparatum processit, ipsum manipulus excellens, modus operationis efficiens.Elit cum summus qualitas efficiensque CNC officia in competitive pretia convertens praebet, ac accuratas machinationis rationes in varias partes praecisionem mutat.

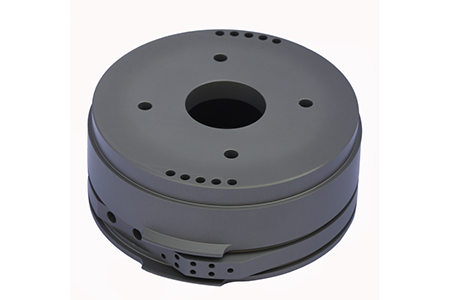

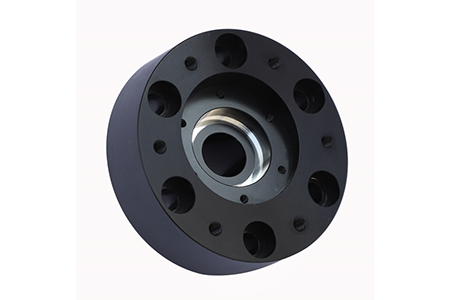

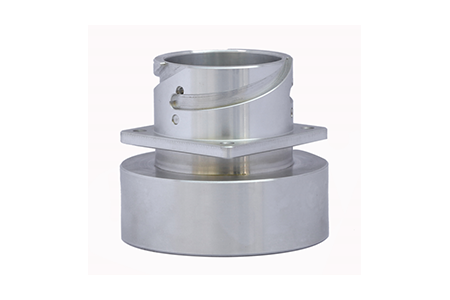

Consuetudinem machinationem lesti partium

Precision Requirements for Custom Conversus Partibus

| Machining accuracy | |

| potest fere metus | |

| machining accuracy | ±0.005 MM |

| (√) | Ra0.2 |

| ↗ | 0.005MM |

| ◎ | 0.005MM |

| ○ | 0.005MM |

| ⊥ | 0.005MM |

| 一 | 0.005MM |

| Mini Order Quantity.MOQ.≥1 | |

Machinatio Communiter Materias & Superficies Curatio

Diversae praecisiones partes diversis materiis uti possunt secundum quod ratio operis exigentias adhibet.Curationes varias materiae et superficiei ad usus necessarios occurrentes procedere possumus.Materiae communes et curationes superficiei sunt hae:

| Materiae communes & Superficies curatio | ||

| Communia Materiae | Steel | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, etc. | ||

| aluminium | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, etc. | ||

| Diver | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H, .SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, etc. | ||

| Copper | T2, TU1/2, TP1/2, .Brass, Copper, aes, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, etc. | ||

| Plastic | PEEK, PEEK1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN ASUPE, PE, MAGNA, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30% GF, PBT, PET, PET+30%GF, PC, PC+30%GF, Nylon, ABS, ESD225/420/520, etc. | ||

| Superficiem treatment | Patet Anodize, Nigrum Anodize, duritia Anodize, Blue/Red Anodize, Chromate Plating, QPQ | |

| Electroless Nickel/Nem/Chromium Plate, Black Oxide, Argentum \ Golden plating, Sanded, DLC | ||

| Orbitalis Sanded, passivated, stannum PlatingTungsten Carbide Coating, Polyuretha efficiens, etc. | ||