Layanan ngowahi CNC

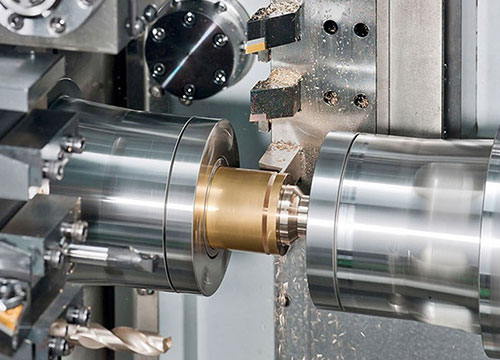

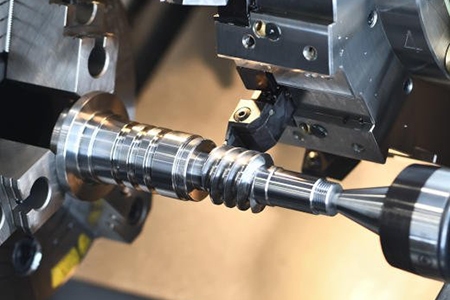

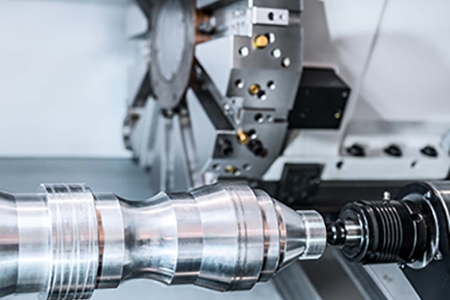

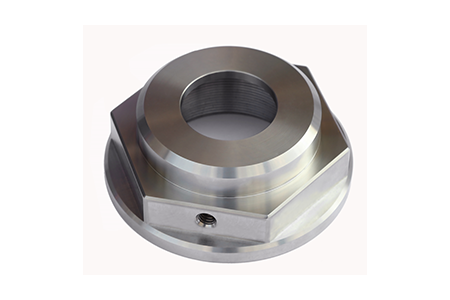

CNC Turning utamané dipigunakaké kanggo nglereni lumahing silinder njero lan njaba saka bagean batang utawa bagean disk, lumahing conical njero lan njaba saka ngarepke conical kasepakatan, Komplek Rotary lumahing sudhut mlengkung njero lan njaba, silinder, Utas conical, etc. program Processing, iku bisa ngolah bagean tliti kayata grooving, pengeboran, reaming, reaming lan boring.

± 0.005MM (√)Ra0.2

Mesin CNC Nduwe Karakteristik Ing ngisor iki

● Tliti Processing dhuwur lan kualitas Processing stabil;

● Bisa nindakake pranala multi-koordinat, otomatisasi tingkat dhuwur, lan bisa ngolah bagean kanthi bentuk kompleks;

● Nalika ngganti bagean Processing, umume mung kudu ngganti program NC, kang bisa ngirit wektu preparation produksi lan nambah efficiency;

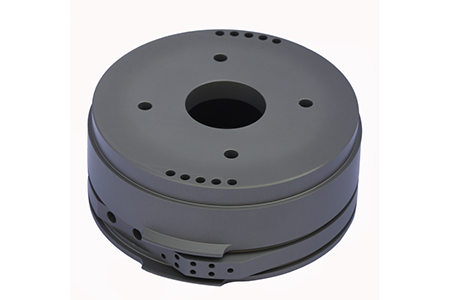

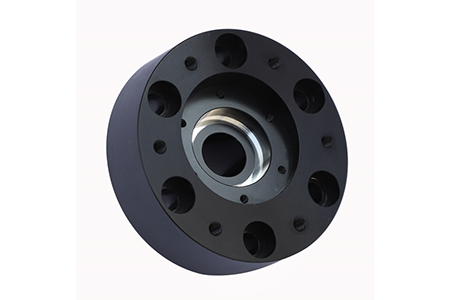

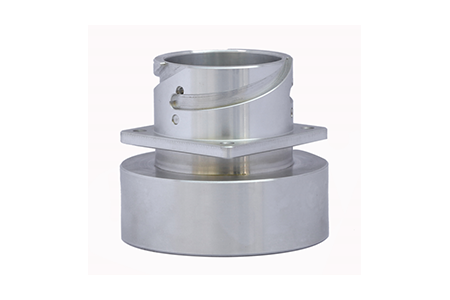

Bagean Mesin Presisi Kanthi Kualitas Dijamin

K-TEK nduweni peralatan pangolahan canggih, tim teknik sing apik, lan mode operasi sing efisien.Nyedhiyakake pelanggan kanthi layanan ngowahi CNC sing berkualitas lan efisien kanthi rega sing kompetitif, lan ngowahi gambar desain teknik sing tliti menyang macem-macem bagean presisi.

Mesin khusus saka bagean lathe

Requirements Precision kanggo Custom Nguripake Parts

| Akurasi mesin | |

| umume bisa nyukupi syarat | |

| akurasi mesin | ± 0,005 MM |

| (√) | Ra0.2 |

| ↗ | 0,005 MM |

| ◎ | 0,005 MM |

| ○ | 0,005 MM |

| ⊥ | 0,005 MM |

| 一 | 0,005 MM |

| Mini Order Quantity(MOQ)≥1 | |

Permesinan Bahan sing Umum Digunakake & Perawatan Lumahing

Bagean presisi sing beda bisa nggunakake bahan sing beda-beda miturut syarat desain produk.Kita bisa ngolah macem-macem bahan lan perawatan permukaan kanggo nyukupi kabutuhan pelanggan.Bahan umum lan perawatan permukaan kaya ing ngisor iki:

| Bahan umum & perawatan lumahing | ||

| umum Bahan | baja | 20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, lsp. | ||

| alumunium | LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, lsp. | ||

| Baja tahan karat | SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H,,SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4 jam, 430F, X90CrMoV18, 9Cr18MoV, SUS440, lsp. | ||

| Tembaga | T2, TU1/2, TP1/2,,Kuningan, Tembaga, gangsa, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, lsp. | ||

| Plastik | NGIPI, IKI 1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, PET, PET + 30% GF, PC, PC+30%GF, Nylon, ABS, ESD225/420/520, lsp. | ||

| Pangobatan lumahing | Clear Anodize, Anodize ireng, Anodize kekerasan, Anodize Biru/Abang, Kromat Plating, QPQ | |

| Plate Nikel / Nine / Kromium Tanpa Elektro, Oksida Ireng, Silver\Gold plating, Sanded, DLC | ||

| Orbital Sanded, Pasif, TIN PlatingTungsten Carbide Coating, Lapisan polyurethae, lsp. | ||