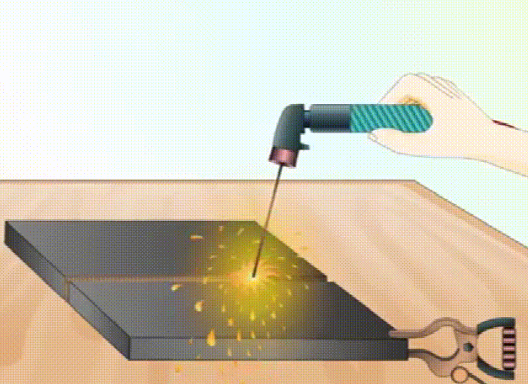

1, Electrode arc vuam

Arc welding yog ib qho ntawm cov kev txawj ntse tshaj plaws uas welding tswv, yog tias tsis muaj kev txawj ntse, yuav muaj ntau yam tsis xws luag hauv vuam seam.

2, Submerged arc vuam

Submerged arc vuam yog ib txoj kev vuam siv arc ua qhov cua sov. Vim qhov tob tob ntawm submerged arc vuam, qhov vuam zoo yog qhov zoo: vim yog kev tiv thaiv ntawm molten slag, cov hlau melted tsis nyob rau hauv kev sib cuag nrog huab cua, thiab cov degree ntawm mechanization ua hauj lwm yog siab, yog li nws yog haum rau vuam. ntev welds ntawm nruab nrab thiab tuab phaj qauv.

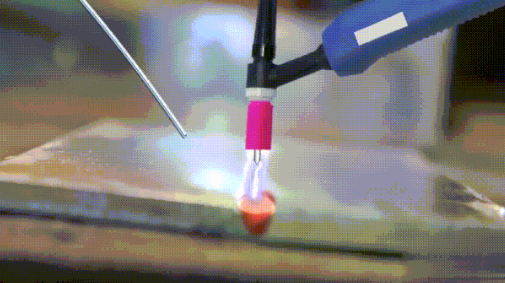

3. Argon arc vuam

Nov yog qee qhov kev ceev faj rau argon arc vuam:

(1) Lub koob tungsten yuav tsum tau sharpened ntau zaus. Yog hais tias nws yog blunt, tam sim no yuav tsis concentrated thiab welding yuav tiav.

(2) Yog tias qhov kev ncua deb ntawm rab koob tungsten thiab cov vuam yog ze dhau, lawv yuav ua ke. Yog tias nws nyob deb dhau, lub arc yuav tawg. Thaum lub arc blooms, nws yuav hlawv dub thiab tungsten koob yuav bald. Cov hluav taws xob rau tus kheej kuj muaj zog. Nws yog qhov zoo dua kom nws nyob ze.

(3) Kev tswj ntawm qhov hloov pauv yog ib qho kev kos duab, tshwj xeeb tshaj yog rau nyias phaj vuam. Nws tsuas tuaj yeem tig rau ntawm ib qho los ntawm ib qho. Qhov no tsis yog lub tshuab vuam tsis siv neeg uas tsis siv neeg txav thiab tsis siv neeg hlau pub. Yog hais tias nws hlawv tsis tu ncua, nws yuav lwj.

(4) Koj yuav tsum tau noj cov hlau. Qhov no yuav tsum muaj kev nkag siab. High-zoo vuam hlau yog txiav los ntawm 304 daim hlau nrog lub tshuab shearing. Tsis txhob yuav nws hauv pob khoom. Tau kawg, koj tuaj yeem nrhiav cov khoom zoo ntawm cov khoom lag luam wholesale.

(5) Sim ua haujlwm hauv qhov cua, hnav hnab looj tes tawv, khaub ncaws, thiab lub ntsej muag tsis siv neeg dimming.

(6) Lub taub hau ceramic ntawm rab phom vuam yuav tsum tau tiv thaiv los ntawm arc. Tshwj xeeb, tus Tsov tus tw ntawm rab phom vuam yuav tsum tau taw rau koj lub ntsej muag ntau li ntau tau.

(7) Yog tias koj tuaj yeem muaj qhov kev xav thiab premonition txog qhov kub thiab txias, qhov loj me, thiab kev ua ntawm lub pas dej molten, koj yog tus kws tshaj lij laus.

(8) Sim siv cov koob tungsten nrog cov cim daj lossis xim dawb, vim qhov no yuav tsum muaj kev ua haujlwm siab.

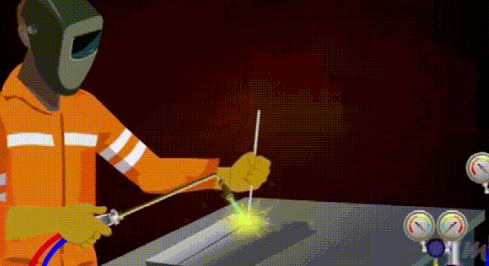

4. Cov pa roj carbon monoxide welding

Cov pa roj carbon monoxide welding yog siv cov nplaim taws kom sov cov hlau thiab vuam hlau ntawm qhov sib koom ua ke ntawm cov hlau ua haujlwm kom yaj lawv thiab ua tiav lub hom phiaj ntawm vuam. Feem ntau siv cov combustible gases feem ntau yog acetylene, liquefied petroleum gas thiab hydrogen, thiab feem ntau siv combustion-txhawb roj yog oxygen.

5. Laser vuam

Laser welding yog ib qho kev siv tau zoo thiab muaj tseeb uas siv lub tshuab hluav taws xob muaj zog-density laser beam ua qhov cua sov. Laser vuam yog ib qho tseem ceeb ntawm kev siv cov khoom siv laser ua tshuab. Nyob rau xyoo 1970, nws tau siv los ua cov ntaub ntawv nyias nyias thiab vuam qis. Cov txheej txheem vuam yog ib hom hluav taws xob hluav taws xob, uas yog, cov hluav taws xob laser heats saum npoo ntawm qhov chaw ua haujlwm, thiab cov cua sov saum npoo diffuses mus rau sab hauv los ntawm kev ua cua sov. Los ntawm kev tswj qhov dav, lub zog, lub zog siab tshaj plaws thiab rov ua dua zaus ntawm lub laser pulse, lub workpiece yog yaj los ua ib lub pas dej ua ke.

Post lub sij hawm: Oct-22-2024