Menene fasahar CNC don injin CNC?"CNC" fasaha ce mai sarrafa dijital ta kwamfuta a cikin Turanci, an taƙaita ta da CNC.Hanyar injinan CNC na nau'in sassaƙa ne da siffa, kuma mashin ɗin madaidaicin sassa ne na'ura mai amfani da yawa a masana'antu kamar motoci, sadarwa, kiwon lafiya, agogo, wayar hannu, kwamfutoci da sauransu. kuma mafi dacewa da masana'antu tare da madaidaicin buƙatun.Sarrafa sassa na inji gabaɗaya yana nufin jimillar tsarin haɗuwa na lambar ɓangaren da kukan inji.Sauran hanyoyin ana kiran su matakan taimako, kamar sufuri, ajiya, samar da wutar lantarki, kula da kayan aiki, da sauransu.

Ana yin aikin injuna na gargajiya ta hanyar aiki da hannu na kayan aikin injuna na yau da kullun.A lokacin aikin injin, ana girgiza kayan aikin injin da hannu don yanke ƙarfe kuma ana auna daidaiton samfurin ta amfani da kayan aiki irin su calipers.Masana'antar zamani ta yi amfani da kayan aikin injin sarrafa lambobi don aiki, waɗanda masu fasaha za su iya sarrafa su.Shirin da aka tsara ta atomatik yana sarrafa kowane samfur da sashi.

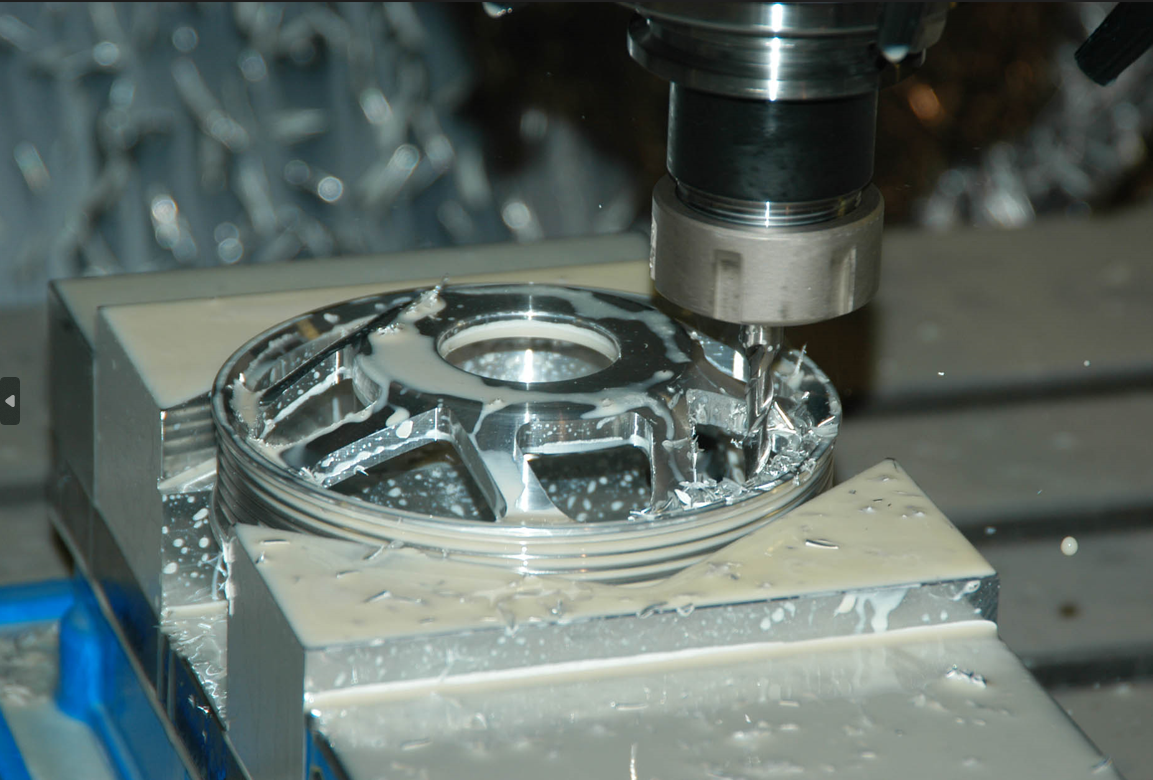

Hanya ce ta yin amfani da bayanan dijital don sarrafa motsi da sarrafa kayan aikin injin, ta amfani da fasahar CNC don sarrafa kayan aikin injin, ko kayan aikin injin da ke da tsarin CNC ana kiransa kayan aikin injin CNC.Daga cikin su, tsarin kayan aikin injin CNC ya haɗa da: Na'urar kayan aikin injin CNC, mai sarrafa shirye-shirye, na'urar tuƙi, da na'urar ciyarwa.Kayan aikin injin CNC sune samfuran haɗe-haɗe na inji, lantarki, na'ura mai aiki da karfin ruwa, huhu, gani, da sauran filayen.Don sarrafa kayan aikin injin, ana buƙatar bayanan geometric don kwatanta motsin dangi tsakanin kayan aiki da kayan aiki a cikin injinan CNC.Ana amfani da bayanan tsari don bayyana wasu sigogin tsari waɗanda dole ne a ƙware a cikin injin kayan aikin injin, kamar ƙimar abinci, saurin igiya, jujjuyawar gaba da juyawa, canjin kayan aiki, sauyawa mai sanyaya, da sauransu, waɗanda aka adana a cikin wani tsari na mashin ɗin. fayiloli (watau shirye-shiryen inji na CNC) akan masu ɗaukar bayanai (kamar fayafai, kaset masu zafi, kaset na maganadisu, da sauransu).Sannan, tsarin CNC yana karanta kayan aikin injin, ko shigar da shi kai tsaye ta hanyar maballin tsarin CNC ko ta hanyar shigar da sadarwa.Ta hanyar yanke hukunci, kayan aikin injin yana motsawa da sarrafa sassa.

Kayan aikin injin na CNC na zamani sune samfuran lantarki na yau da kullun, waɗanda sune tushen fasaha na sabon ƙarni na fasahar samarwa da haɗaɗɗen masana'anta na kwamfuta.Ko dai shigar da kai tsaye ta hanyar madannai na tsarin CNC, ko ta hanyar shigar da sadarwa, yanke hukunci don matsar da kayan aikin injin don sarrafa sassa.Kayan aikin injin CNC na zamani sune tushen sabbin fasahar samar da saniya da fasahar hada-hadar kwamfuta.Ko dai shigar da kai tsaye ta hanyar madannai na tsarin CNC, ko ta hanyar shigar da sadarwa, yanke hukunci don matsar da kayan aikin injin don sarrafa sassa.Kayan aikin injin na CNC na zamani sune samfuran lantarki na yau da kullun, waɗanda sune tushen fasaha na sabon ƙarni na fasahar samarwa da haɗaɗɗen masana'anta na kwamfuta.Haɓakawa na kayan aikin injin CNC na zamani yana da sauri, daidaitaccen tsari, babban aminci, multifunctional, composite, mai hankali, da tsarin buɗewa.Babban yanayin ci gaba shine haɓaka na'urorin CNC na duniya masu hankali da cikakken aiki tare da buɗe software da sigar kayan masarufi.Fasahar CNC ita ce tushen injin sarrafa kayan aiki da kuma ainihin fasahar kayan aikin injin CNC.Matsayinsa yana da alaƙa da tsarin dabarun ƙasa kuma yana nuna ƙarfin ƙasa gaba ɗaya.Ya haɓaka tare da haɓaka fasahar bayanai, fasahar microelectronics, fasahar sarrafa kansa, da fasahar ganowa.CNC machining Center wani nau'i ne na kayan aikin injin CNC tare da ɗakin karatu na kayan aiki, wanda zai iya canza kayan aiki ta atomatik kuma ya yi ayyuka daban-daban na machining akan kayan aiki a cikin wani kewayon.Saboda ƙaddamarwa da kuma kammala atomatik na matakai da yawa ta cibiyar mashin ɗin, ana guje wa kurakurai na aiki na ɗan adam, yana rage lokacin matse kayan aiki, aunawa, da daidaita kayan aikin injin.CNC machining, kazalika da ƙwarai inganta juzu'i, handling, da kuma ajiya lokaci na workpieces, ƙwarai inganta yadda ya dace na CNC machining.

Lokacin aikawa: Mayu-24-2024