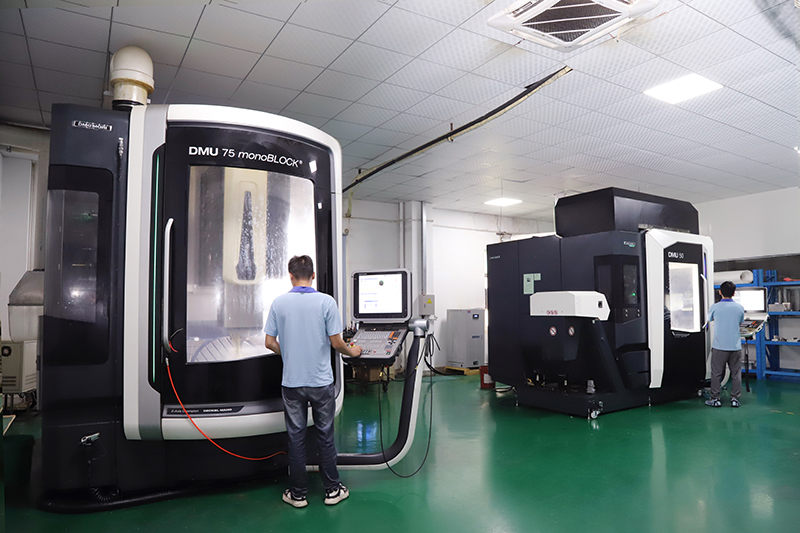

5 Axis CNC Machining Services

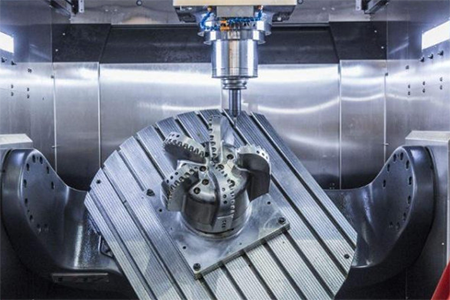

K-TEK has introduced world’s ultra precision machine-DMG 5-Axis Machining Center since 2018 in order to meet high requirements on different industries.5-axis machines rely on a tool that moves in five different directions — X, Y, and Z, as well as A and B, around which the tool rotates. Using a 5-axis CNC machine lets operators approach a part from all directions in a single operation, eliminating the need to manually reposition the workpiece between operations. 5-axis CNC machining saves time and is ideal for creating complex and precise parts like those found in the medical oil and gas, and aerospace industries. Indexed 5-axis machining is great for manufacturing spatial surface, special-shaped, hollow, punching, oblique hole and oblique cutting.

±0.005MM

(√)Ra0.2

Advantages of 5-axis machining

1.High precision and fast efficiency

5-axis machining has high precision and fast efficiency. It can not only complete the processing tasks of various composite parts from different industrial products, but also reduce the clamping times and the processing flow as well as control product quality well,which helps us save lots of cost and make us more competitive .Many precision parts need to process multiple surfaces and 5-axis can reach these processing requirement with saving a lot of time, reducing the production cycle and quickly completing customer delivery.

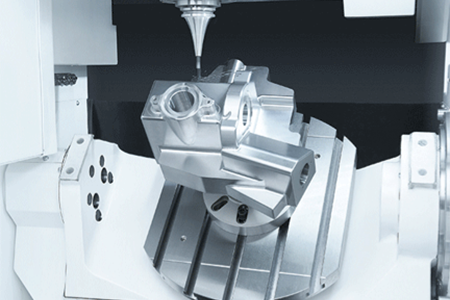

2.Improve accuracy and processing precision

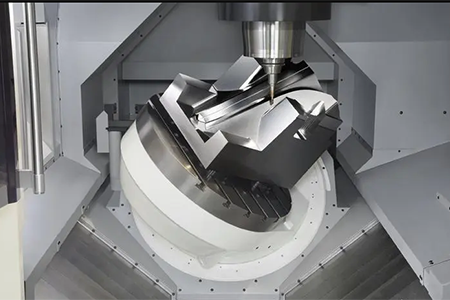

Not only do these types of 5-axis CNC milling machines offer greater accuracy when machining deeper parts and hardened materials, but they also offer higher yields and faster machining speeds. However, 5-axis machining is more expensive due to the specialized equipment necessary and the need for expert workers.

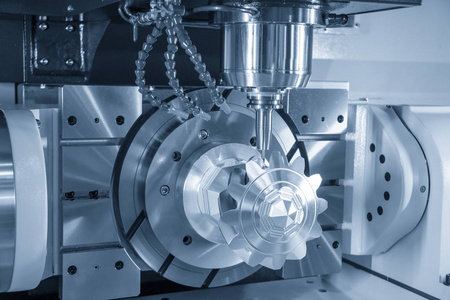

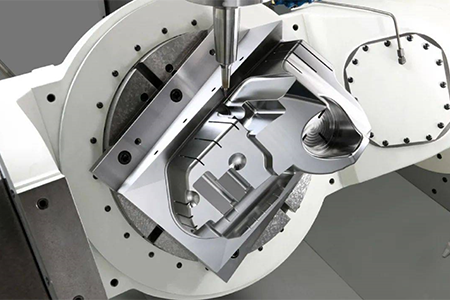

Through 5-axis machining technology, the problem of multiple repositioning accuracy of workpieces with complex angles is solved. Not only has the time been shortened, but the machining thin tolerances have been well solved . 5-axis machining can process complex parts, such as drilling, taper processing, cavities and grooves with complex curved surfaces, etc., which cannot be achieved by traditional processing methods in most cases.

3. High quality finish

5-Axis machining also helps to create surfaces with a high-quality finish. Parts are placed closer to the cutting tools in the 5-axis machine, which don't vibrate as much, resulting in a high-quality surface finish. processing accuracy can be controlled within ±0.002MM, surface roughness (√) control in Ra0.2.

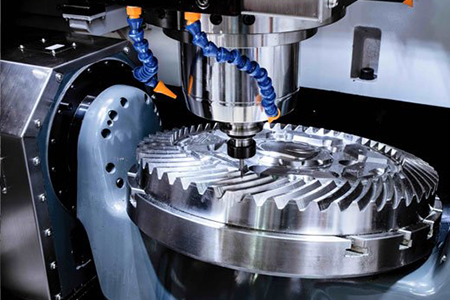

4.High processing efficiency

5-axis machining can effectively reduce the processing time and auxiliary time of parts. It has a large spindle speed and feed range, so that the machine has a strong large cutting ability. The fast movement and positioning of five-axis machining and high-speed cutting machining help reduce the turnaround time of semi-finished products and improve production efficiency and accuracy. In the face of a variety of complex precision parts processing to provide us with effective production solutions, while efficiency and quality has also brought great improvement, through CNC milling services to customers product design or ideas into reality, materials involving a variety of metals and plastics and a variety of surface treatment.

10+ Years of 5-Axis Cnc Machining Experience and Engineering Team

Quotation:3 hours quote, 5 hours manufacturing feasibility solution service and advice.

Engineering and Design:Free to assist customers to optimize product structure and design 3D drawings.

Custom Designs:Manufacture any complex precision 5-axis CNC machined parts based on customer drawings and samples.

Efficiency:The factory is fully equipped with equipment, and a variety of CNC machining methods are combined to improve the processing efficiency and quickly complete the delivery.

Sample Delivery:Deliver samples in one week, record sample problems, and make mass production smooth.

Quality Assurance: Every job goes through a rigorous quality testing process. Inspection tool includes 3D CMM measuring instrument, altimeter, quadratic element, etc. From initial engineering review DFM, pre-production, IQC, first article, manufacturing process to final inspection, we strictly control quality to ensure quality. Refined production standards provide you with 5-axis CNC machining parts with a precision pass rate of up to 99%.

Quality Service:Every production run is well documented and shared transparently with the customer.

5 Axis CNC Machining Commonly Used Materials

5-axis CNC can process a variety of materials, if you do not know how to choose the right material, our engineers can also recommend the right material for you according to your manufacturing needs and the performance of 5-axis CNC machining parts. The following are our commonly used processing materials, we can also process other materials according to customer needs.

|

Common materials & Surface treatment |

||

|

Common Materials |

Steel |

20#, Q235, 45#, A2, D2, 16MnCr5, 30CrMo, 38CrMo, 40CrNiMo3, S50C, 65Mn, SCM415, 40Cr, Cr8 |

| Cr12, SKD61, DC53, 12L14, Y12pb, Y15, Y35, Y40Mn, S5, T10, S355, 16MnCr5 | ||

| 6150, SCM435, St37, 410, 416, 420, 430, 4140, 4130, 240N, Stell, SKS3, 38CrMOAl, 20CrNiMo | ||

| P20, SUJ2, SK3, 15CrMo, 20CrMo, 35CrMo, GS2316, CD650, ASP-23O1, A6, XW-5, XW-10, XW-41 | ||

| C1065, NAK55, NAK80, HPM1, HPM77, HPM75, 718H, 738H, DF-3, etc. | ||

|

Aluminum |

LY12, 2A12, A2017, AL2024, AL3003, AL5052, AL5083, AL6061, AL6063, AL6082, AL7075, YH52 | |

| YH75, MIC-6, etc. | ||

|

Stainless Steel |

SUS201, SUS321, SUS301, SUS303, SUS304, SUS304L, S136, S136H, , SUS316, SUS316L, SUS316Ti | |

| SUS321, SUS420, 17-4ph, 430F, X90CrMoV18, 9Cr18MoV, SUS440, etc. | ||

|

Copper |

T2, TU1/2, TP1/2, , Brass, Copper, Bronze, CuZn38Sn1, CuZn39Pb3, CuSn12, CuSn8P, C-360 | |

| CuSn7ZnPb, CuZn38Pb2, C36000, C1100, C1011, C1020, C1201, C1220, C2800, C3602, HPb59-1 | ||

| HPb61-1, QSn7-02, C-954/514QAI 10-4-4, AMPCOM4, H59, H62, CuZN30, CuSn37, etc. | ||

|

Plastic |

PEEK, PEEK1000, POM, TEFLON, PTFE, PET, UHMW-PE, HMW-PE, PEI, PI, PP, PVC, PC, PMM, APS, PU | |

| FR4, DELRIN, DELRIN AFUPE, PE, UPE, EKH-SS09, MC501CDR6, PPO, NBR, PA6, PA66, FR4, PA-MC | ||

| PA66+30%GF, PBT, PET, PET+30%GF, PC, PC+30%GF, Nylon, ABS, ESD225/420/520, etc. | ||

|

Surface treatment |

Clear Anodize, Black Anodize, Hardness Anodize, Blue/Red Anodize, Chromate Plating, QPQ | |

| Electroless Nickel/Nine/Chromium Plate, Black Oxide, Silver\Golden plating, Sanded, DLC | ||

| Orbital Sanded, Passivated, TIN PlatingTungsten Carbide Coating, Polyurethae coating, etc. | ||

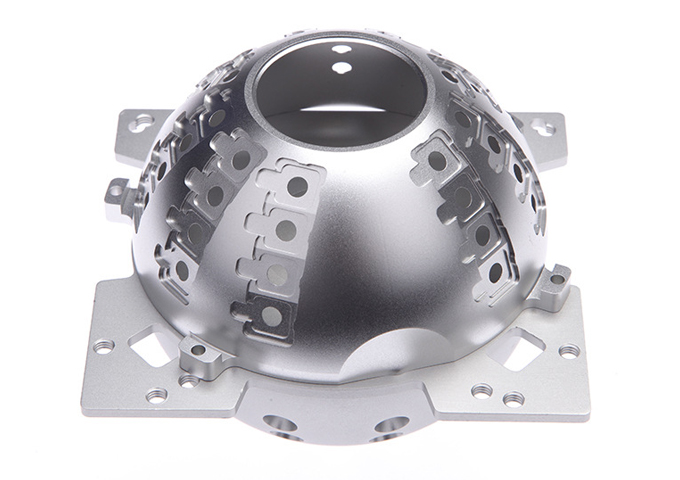

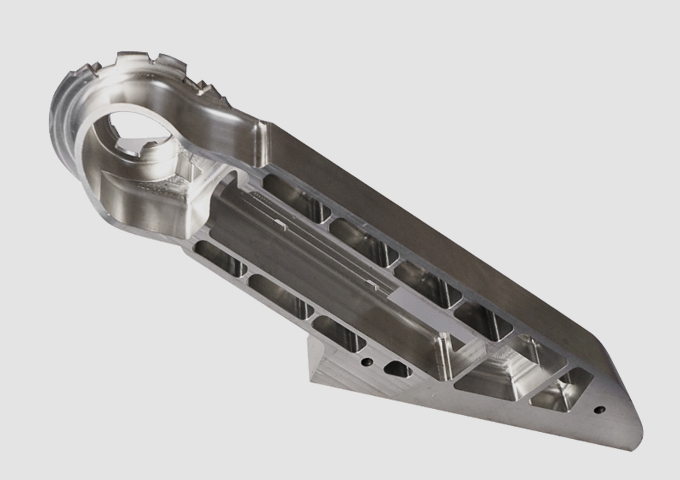

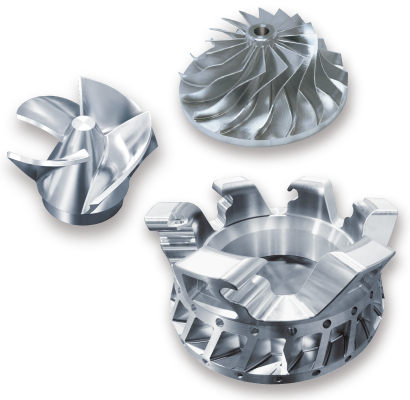

Case Show

K-Tek is mainly engaged in the custom processing of multi-variety and small-batch mechanical parts, all parts are done according to the needs of customers. Here are some processing cases that we have produced before:

Aluminum products processing products

Steel product processing parts

Stainless steel product processing parts

Copper & Plastic product processing parts