about us

ABOUT US

K-TEK founded in 2007, specializes in machining various precision machinery parts, which can be customized according to customers’ drawings or samples. The company has more than 10 years of precision machining experience, relying on ISO2009:2015 quality management system, strict quality control to provide customers with OEM/ODM services, product processing accuracy can be controlled within ±0.002MM, surface roughness (√) control in Ra0.4. We mainly focus on a variety of precision parts customized processing, focusing on a variety of small batch production, while the number of products is completely without any requirements, one can also be processed, which is our competitive advantage! Please provide the drawing (PDF, CAD) and quantity to us, we will give you a quotation within 12 hours.

Processing common materials:

-

1.Steel (as):

A2、D2、16MnCr5、30CrMo、38CrMo、z40CrNiMo3、St50、65Mn、SCM415、 S235JR、SKS3、Y12、St37、240N, etc.

-

2. Aluminum(as):

AL2017、AL2024、AL5052、AL5083、AL6061、AL6082、AL7075, etc.

-

3. Stainless(as):

SUS303/304、SUS316、SUS321、17-4ph、430F、 X90CrMoV18, etc.

-

4. Copper(as):

Brass、Copper、CuZn39Pb3、CUSN12、CuSn8、CuSn7ZnPb、CuSn37, etc.

-

5. Plastics(as):

PEEK、POM、PTFE、PET、PE、PVC、PC、FR4、PA6、PP、ABS, etc.

Founded in

Ra 0.

Control in

years

Machining experience

±0.00 mm

Accuracy can be controlled within

WHY CHOOSE OUR SERVICES

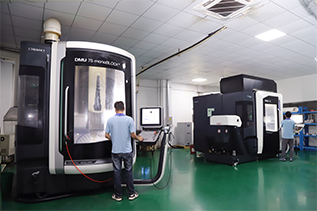

K-Tek is a professional precision machine parts processing company with more than 10 years of processing experience. It has a professional core team and advanced equipment and has passed the ISO9001:2015 certification. K-TEK has introduced ERP system that tracks entire process of our components from product arrangement to shipment such as raw materials, production capacity—and the status of business commitments: orders, purchase orders,status of production and shipment.

Engineer Team

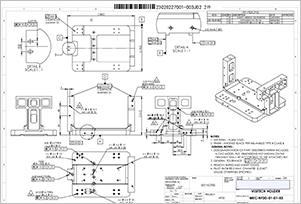

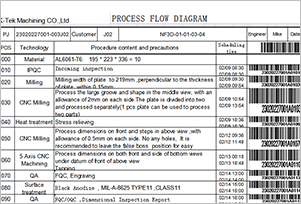

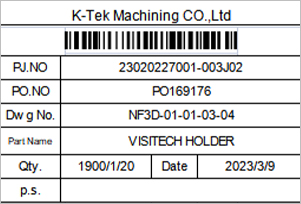

K-tek has an experienced engineering team to carefully review the incoming drawings as well as communicate with customers if there is any problem, and then formulate the best process flow for each part, ,input the ERP system to generate an electronic form. Ensure to provide customers with qualified products under the strict control of each process. Such as:

Processing Capacity

K-Tek team keeps improving and continuously optimizes the production process , use precision machine such as Five-axis Machine (DMG), CNC Milling, CNC Turning, WEDM-LS, EDM, Grinder, Milling, Turning, Grinding, etc from Germany, Japan,American, to manufacture components and improve the quality stability as well as production efficiency of the production ,The processing accuracy of the product can be controlled at ±0.002MM, and the surface coarse grain size (√) can be controlled at Ra0.2.

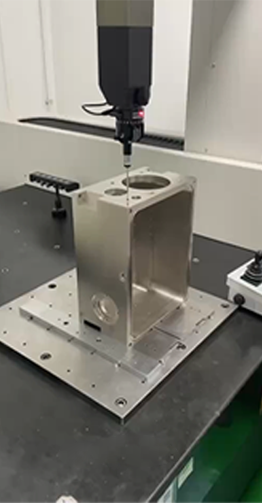

QUALITY CONTROL

K-Tek has passed ISO2009:2015 certification and complies with the ISO quality control system, strictly controls the quality and reduces defective products in each production process, so as to improve production efficiency and reduce processing costs, finally provide customers with reliable and competitive products s price. K-Tek has also introduced various testing tools to improve the quality stability such as CMM、HeightGauge、Material Analyzer、Hardness Tester、 Glossmeter、Micromete.,etc.

Delivery and After-sales Services

Each parts is processed according to the process card and under strict quality supervision. Each process will be scanned and entered into the system in time to ensure delivery on schedule.For customer complaints, K-Tek always communicates with customers in time and gives feedback within 12 hours.

BUSINESS OPERATION PROCESS

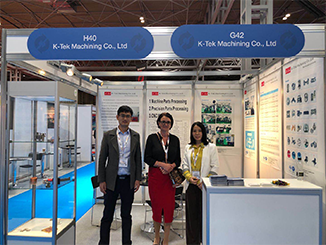

MEET US AT EXHIBITION

After ten years of development, K-TEK not only has a large number of professional and technical personnel and excellent management team, but also has a very excellent sales team. In order to let more customers know us, we regularly go to the world to participate in exhibitions, such as: the United States, the United Kingdom, Germany, Japan and so on. We got to know a large number of customers from the exhibition, at the same time, many foreign customers came to visit K-TEK factory and discuss cooperation matters. Your support is the greatest encouragement to us. We also hope to provide high-quality machining services for more customers in need. We sincerely invite you to cooperate and develop together.

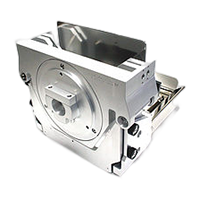

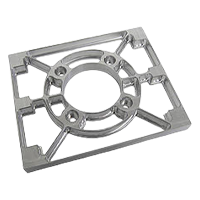

Customer sample

K-TEK shares some processing cases, all of which are machined according to customers’ drawings. The processing machine involves 5 Axis CNC Machining / CNC Milling/CNC Turning/Heat treatment /Surface treatment and other processes. The processing accuracy can be controlled at ±0.002MM and surface roughness (√) is controlled at Ra0.2. K-TEK has a strong processing capacity and strict quality control system. Please freely to reach us out.

Welcome to contact us

K-TEK provides precision milling and turning parts services, providing professional machining services at competitive prices and timely delivery. With our strong machining capacity, the production of precision parts can meet the requirements of various equipment parts, products cover a variety of mechanical equipment, automation equipment, fixture and other industries.